அக் . 02, 2024 08:21 Back to list

what is hpmc made from

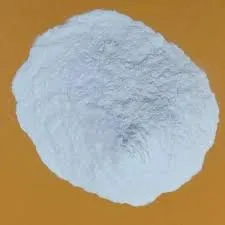

HPMC, or Hydroxypropyl Methylcellulose, is a versatile cellulose ether that is widely utilized in various industries, including pharmaceuticals, food, cosmetics, and construction. This compound is derived from natural cellulose, a polymer that makes up the cell walls of plants. The transformation from cellulose to HPMC involves a series of chemical modifications, primarily the introduction of hydroxypropyl and methyl groups, which not only enhance its solubility but also improve its functional properties.

To understand what HPMC is made from, we need to first look at its precursor cellulose. Cotton and wood pulp are two common sources of cellulose. The production of HPMC typically begins with the extraction of cellulose from these natural sources. The extracted cellulose is then subjected to a process called etherification, which involves reacting cellulose with propylene oxide and methyl chloride. This process modifies the structure of the cellulose, resulting in HPMC.

.

In the food industry, HPMC is used as a thickener, emulsifier, and stabilizer. It can help improve the texture and shelf life of food products. For example, it is often found in baked goods, sauces, and dressings, where it contributes to the desirable viscosity and mouthfeel. Its non-toxic and biodegradable nature makes it a preferred choice for food applications, particularly in the context of clean label trends where consumers are increasingly looking for natural ingredients.

what is hpmc made from

In cosmetic formulations, HPMC serves as a thickener and a film-forming agent, enhancing the overall texture of creams, lotions, and gels. Its moisturization properties are beneficial in personal care products, helping to create a pleasant sensory experience for the user.

The construction industry also benefits from HPMC, particularly in the manufacturing of cement-based products like mortars and plasters. Its ability to retain water and enhance the workability of mixtures makes it an important component in these applications.

In summary, HPMC is made from natural cellulose obtained from sources like cotton and wood pulp through a chemical modification process. Its diverse applications across various industries underscore its importance as a functional excipient, providing benefits like improved viscosity, stability, and texture. As research and development in this field continue to evolve, HPMC remains a crucial ingredient in modern formulations.

-

tile-bonding-additives-for-stronger-bonds

NewsAug.22,2025

-

construction-grade-rdp-for-wholesale-needs

NewsAug.22,2025

-

trusted-wholesale-hec-partners

NewsAug.22,2025

-

hec-solutions-for-industrial-excellence

NewsAug.22,2025

-

construction-additives-need-hpmc-essentials

NewsAug.22,2025

-

hpmc-versatile-cellulose-ether-for-industries

NewsAug.22,2025