Novemba . 06, 2024 15:58 Back to list

Exploring the Benefits of Redispersible Polymer Powder in Construction Applications

Understanding Redispersible Polymer Powder (RDP)

Redispersible Polymer Powder (RDP) has become a key ingredient in various industries, particularly in construction, adhesives, and coatings. As a finely ground polymer, RDP exhibits unique properties that enhance the performance and sustainability of products. This article seeks to explore the composition, benefits, applications, and future trends of RDP.

What is Redispersible Polymer Powder?

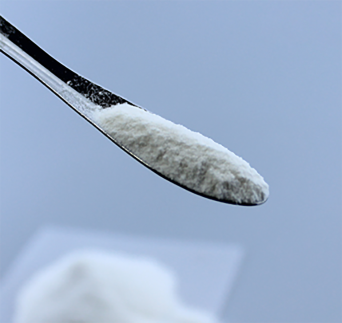

RDP is a water-soluble polymer powder that can be redispersed in water to form a stable emulsion. Typically derived from various polymers such as vinyl acetate, ethylene, and acrylate, RDP is used to modify the properties of cementitious mixtures, paints, and adhesives. This powder is produced through a process called spray-drying or freeze-drying, which leads to the formation of a fine, white powder that is easy to transport and store.

Key Benefits of RDP

1. Versatility One of the primary advantages of RDP is its versatility. It can be tailored to meet specific performance requirements, making it suitable for a wide range of applications. Depending on the formulation, RDP can enhance adhesion, flexibility, and water resistance.

2. Improved Workability RDP significantly improves the workability of construction materials. When incorporated into cementitious formulations, it enhances the mixture's processing characteristics, enabling better application and finish.

3. Enhanced Durability RDP contributes to the mechanical strength and durability of the final product. It forms a cohesive film that binds the particles together, resulting in improved resistance to crack formation and thermal changes.

4. Reduced VOC Emissions The use of RDP in construction materials and adhesives can lead to reduced volatile organic compound (VOC) emissions, thereby contributing to healthier indoor air quality and compliance with environmental regulations.

5. Cost-Effectiveness Incorporating RDP can improve product performance, allowing manufacturers to produce higher-quality materials without significantly increasing costs. This makes RDP an attractive option for businesses aiming to maximize their return on investment.

redispersible polymer powder rdp

Applications of RDP

RDP is utilized across various industries, highlighting its versatility and effectiveness

. Some common applications include1. Cementitious Systems In the construction industry, RDP is often added to tile adhesives, plasters, and mortars. It enhances adhesion, flexibility, and water retention, making these products more effective and easier to work with.

2. Coatings In paint formulations, RDP provides better film formation, water resistance, and durability. It promotes uniform coverage and adhesion to various substrates, making it ideal for both interior and exterior applications.

3. Adhesives RDP is a valuable component in various adhesive formulations. It improves adhesion properties and enhances the overall performance of the bonding agent, particularly in construction and woodworking applications.

4. Filler and Sealant Products In fillers and sealants, RDP contributes to improved elasticity and water resistance, ensuring that these products perform well in diverse environmental conditions.

Future Trends and Innovations

As industries increasingly focus on sustainability and performance, the demand for RDP is expected to grow. Innovations such as bio-based RDPs are being researched, aiming to reduce reliance on fossil fuels and enhance environmental benefits. Moreover, advancements in polymer chemistry may lead to the development of RDPs with customized properties to meet specific industry demands, such as enhanced resistance to extreme temperatures or improved compatibility with recycled materials.

Conclusion

Redispersible Polymer Powder is an essential ingredient in various applications, providing multiple benefits that enhance product performance and sustainability. Its versatility and effectiveness make it a preferred choice for industries needing reliable and high-quality materials. As technology advances and focuses on environmental considerations, RDP will likely continue to evolve, further solidifying its role in the future of construction, adhesives, and coatings. Embracing these innovations will not only lead to improved product quality but also contribute to a more sustainable approach in product development.

-

The Widespread Application of Redispersible Powder in Construction and Building Materials

NewsMay.16,2025

-

The Widespread Application of Hpmc in the Detergent Industry

NewsMay.16,2025

-

The Main Applications of Hydroxyethyl Cellulose in Paints and Coatings

NewsMay.16,2025

-

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

NewsMay.16,2025

-

HPMC: Application as a thickener and excipient

NewsMay.16,2025

-

Hec Cellulose Cellulose: Multi functional dispersants and high-efficiency thickeners

NewsMay.16,2025