Oct . 31, 2024 04:24 Back to list

hydroxypropyl methylcellulose uses in tablets

The Uses of Hydroxypropyl Methylcellulose in Tablet Formulations

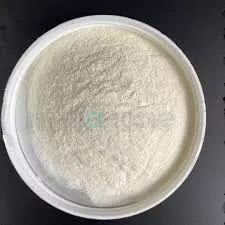

Hydroxypropyl methylcellulose (HPMC) is a versatile polymer that plays a crucial role in the formulation of pharmaceutical tablets

. As a cellulose derivative, HPMC is widely valued for its unique properties, which enhance the performance of tablets in various ways.One of the primary uses of HPMC in tablet formulations is as a binder. Binders are essential in ensuring that the active ingredients and excipients are cohesively held together, providing structural integrity to the tablet. HPMC is particularly effective due to its excellent adhesive properties, which contribute to the formation of a strong tablet under compression. This is crucial for maintaining the tablet's shape and functionality during handling and storage.

In addition to its role as a binder, HPMC also serves as a controlled-release agent. When incorporated into the formulation, HPMC can modulate the release rate of active ingredients. This property is particularly beneficial for developing extended-release formulations, which allow for a gradual release of the drug over time. By controlling the dissolution rate of the tablet, HPMC enhances therapeutic efficacy and improves patient compliance by reducing the frequency of dosing.

hydroxypropyl methylcellulose uses in tablets

Moreover, HPMC is employed as a film-forming agent to create protective coatings on tablets. These coatings not only enhance the aesthetic appeal of the tablets but also protect the active ingredients from environmental factors such as moisture and light, which can degrade their potency. Furthermore, film coatings can mask unpleasant tastes, making the tablets more palatable for patients.

Another significant aspect of HPMC is its role in modifying the viscosity of solutions. When used in liquid formulations or suspensions, HPMC can thicken the product, leading to improved stability and consistency. This characteristic is particularly useful in formulations that require a specific viscosity for optimal delivery and absorption.

HPMC is also known for its safety profile, being non-toxic and devoid of any known adverse effects, which makes it a popular choice in both pharmaceutical and food industries. Its compatibility with various excipients allows for flexibility in formulation development, catering to different drug release profiles and patient needs.

In conclusion, hydroxypropyl methylcellulose is an invaluable ingredient in tablet formulations. Its multifunctional properties as a binder, controlled-release agent, film former, and thickener contribute significantly to the efficiency and effectiveness of pharmaceutical products. As the demand for innovative drug delivery systems continues to grow, the applications of HPMC in tablet formulations are likely to expand, offering enhanced therapeutic solutions for patients worldwide.

-

The Widespread Application of Redispersible Powder in Construction and Building Materials

NewsMay.16,2025

-

The Widespread Application of Hpmc in the Detergent Industry

NewsMay.16,2025

-

The Main Applications of Hydroxyethyl Cellulose in Paints and Coatings

NewsMay.16,2025

-

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

NewsMay.16,2025

-

HPMC: Application as a thickener and excipient

NewsMay.16,2025

-

Hec Cellulose Cellulose: Multi functional dispersants and high-efficiency thickeners

NewsMay.16,2025