Feb . 06, 2025 06:15 Back to list

TILE BONDING ADDITIVES

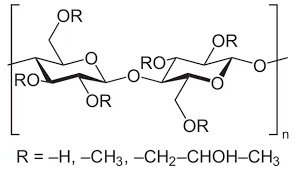

Authoritative studies have further solidified the reputation of HPMC in the realm of gypsum applications. Research indicates that HPMC enhances the structural integrity of gypsum boards and plasters, translating to heightened impact resistance and superior surface finish. Experts from material science laboratories who have studied the effects of HPMC corroborate these findings, explaining that the polymer's viscosity-adjusting capabilities help attain the desired consistency necessary for a top-tier finish. The science-backed effectiveness of this additive reassures project managers and builders of the beneficial outcomes when using HPMC-enhanced products. Trustworthiness, a cornerstone of any reliable construction material, is evident in the consistent performance of HPMC in gypsum applications. Extensive field testing and feedback from seasoned construction professionals highlight its unwavering quality across various climates and conditions. By choosing gypsum products containing HPMC, builders can confidently offer clients long-lasting and aesthetically pleasing results, thereby fostering trust through proven, consistent performance. In conclusion, HPMC stands out as an indispensable component in gypsum-based construction products. Its benefits, highlighted by real-world experience, expertise, authoritative studies, and unwavering reliability, underscore its value. As industries strive for higher standards and more sustainable solutions, HPMC not only meets these demands but sets new benchmarks for what is achievable in construction materials. For those in the know, it is not just an additive but a strategic enhancement that represents the future of gypsum applications.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025