нов . 18, 2024 21:37 Back to list

rdp powder

Understanding RDP Powder Its Significance and Applications

RDP powder, or Redispersible Polymer Powder, has gained significant attention in various industries due to its unique properties and versatility. This additive is primarily used in construction materials, particularly in the formulation of tile adhesives and cement-based products. It plays a crucial role in enhancing the performance and durability of these materials, making it a staple in modern construction practices.

What is RDP Powder?

RDP is a dry powder made from synthetic polymers that, when re-dispersed in water, form a film or matrix around the particles in the mixture. This property allows RDP to improve the mechanical performance and adhesion of construction materials. The powder is created through a spray-drying process, which transforms aqueous dispersions of polymer into a free-flowing powder. The resulting product retains the properties of the original dispersion, including flexibility, water resistance, and adhesion.

Benefits of RDP Powder

1. Enhanced Adhesion One of the most significant advantages of RDP powder is its ability to improve adhesion between materials. In tile adhesives, for instance, RDP enhances the bonding strength between the tiles and the substrate, reducing the risk of delamination over time.

2. Improved Flexibility RDP imparts flexibility to cement-based products. This is particularly important in tile and flooring applications, where movement and thermal contractions are common. The flexibility allows the material to withstand stress without cracking.

3. Water Resistance The presence of RDP enhances the water resistance of various formulations. This is crucial for constructions exposed to moisture, such as bathrooms and kitchens. Improved water resistance also contributes to the longevity of the materials.

4. Workability RDP powder improves the workability of cement-based mixtures. It enables smoother application and reduces the effort required for mixing. This characteristic is particularly favored by professional contractors seeking efficiency on job sites.

rdp powder

5. Compatibility with Other Additives RDP is compatible with various other additives used in construction formulations, such as fillers and pigments. This compatibility allows for personalized formulations that meet specific project requirements.

Applications of RDP Powder

RDP powder is widely used in several construction applications, including

- Tile Adhesives Its excellent bonding properties make RDP a popular choice in tile adhesives, allowing for a strong and durable application.

- Self-Leveling Compounds RDP is added to self-leveling screeds to enhance their flowability and adhesive properties, ensuring a smooth finish.

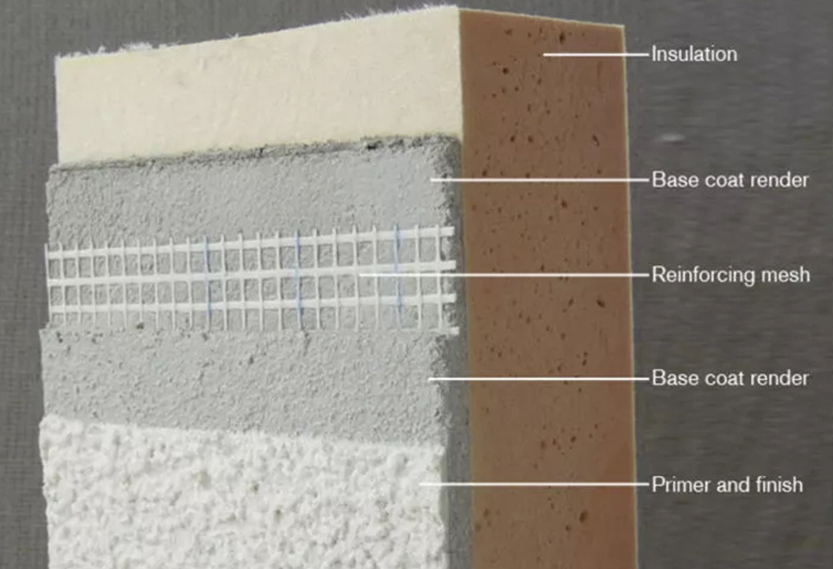

- Rendering and Plastering In external and internal rendering and plastering applications, RDP helps improve adhesion to various substrates while allowing for flexibility and water resistance.

- Repair Mortars RDP is used in repair mortars to provide better adhesion and flexibility, ensuring that repairs withstand movement over time.

Conclusion

In conclusion, RDP powder has proven to be an invaluable additive in the construction industry. Its properties of enhanced adhesion, flexibility, water resistance, and compatibility with other materials make it essential for a variety of applications. As construction practices continue to evolve, the demand for high-performance materials like RDP powder will likely increase, driving further innovation and advancements in the field. Understanding and utilizing RDP can lead to more resilient structures and improved construction processes, ultimately benefiting builders and consumers alike.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025