нов . 11, 2024 05:35 Back to list

HPMC Gelation Temperature and Its Impact on Gel Formation Properties

The Role of HPMC in Gelation Temperature and Its Applications

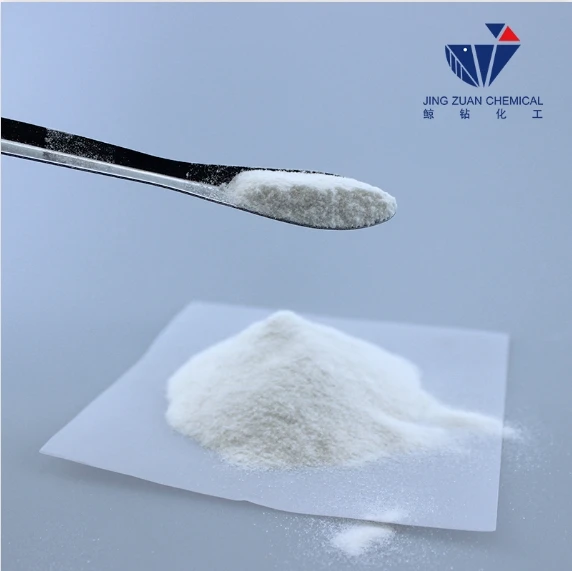

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether widely used in the pharmaceutical, food, and cosmetic industries due to its unique properties, including thickening, emulsifying, and film-forming abilities. One of the critical characteristics of HPMC is its gelation temperature, which plays a pivotal role in determining the material's applicability in various formulations.

The Role of HPMC in Gelation Temperature and Its Applications

HPMC exhibits a unique thermoresponsive behavior; its gelation temperature is sensitive to environmental conditions. Typically, as the temperature increases, HPMC solutions undergo a sol-to-gel transition. This transition is attributed to the hydrophobic interactions among the polymer chains that become more pronounced at elevated temperatures. Understanding the gelation temperature of HPMC is essential for formulators aiming to develop stable and effective products.

hpmc gelation temperature

In pharmaceutical applications, HPMC is often employed as a gel-forming agent in controlled drug delivery systems. The gelation temperature of HPMC can be tailored to ensure that drugs are released at a desired rate and at specific sites within the body. For instance, by adjusting the degree of substitution and molecular weight of HPMC, formulators can modify the gelation temperature, thereby controlling the release profile of active pharmaceutical ingredients (APIs). This ability to fine-tune gelation temperature makes HPMC an ideal candidate for developing innovative drug delivery systems, including hydrogels that respond to physiological heat.

In the food industry, HPMC is commonly used as a thickening agent, emulsifier, and stabilizer. The gelation temperature is crucial in determining the texture and mouthfeel of food products. For example, in low-fat food formulations, where fat is replaced by HPMC to achieve a creamy texture, understanding the gelation behavior allows food scientists to create products that mimic the sensory attributes of high-fat counterparts. Moreover, HPMC's gelation properties can help in creating temperature-stable food items, ensuring consistency in texture despite temperature fluctuations during storage or cooking.

In the cosmetic industry, HPMC is utilized in creams, lotions, and gels, primarily due to its excellent thickening and stabilizing properties. The gelation temperature can influence the application and performance of cosmetic products. By modifying gelation temperature, formulators can design products that deliver active ingredients more effectively or improve the sensory profile of lotions and creams, enhancing user experience.

In conclusion, HPMC's gelation temperature is a crucial parameter that enables the customization of various products across multiple industries. Its ability to transform from a liquid to a gel at specific temperatures allows for the controlled release of drugs, ensures the stability of food products, and enhances the texture of cosmetics. Research is ongoing to further explore and manipulate the gelation behavior of HPMC, with the goal of developing tailored solutions that meet the ever-evolving demands of consumers and industries. As technology advances, the adaptability of HPMC in diverse applications will continue to make it a vital ingredient in formulation science.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025