feb . 19, 2025 12:08 Back to list

TILE BONDING ADDITIVES

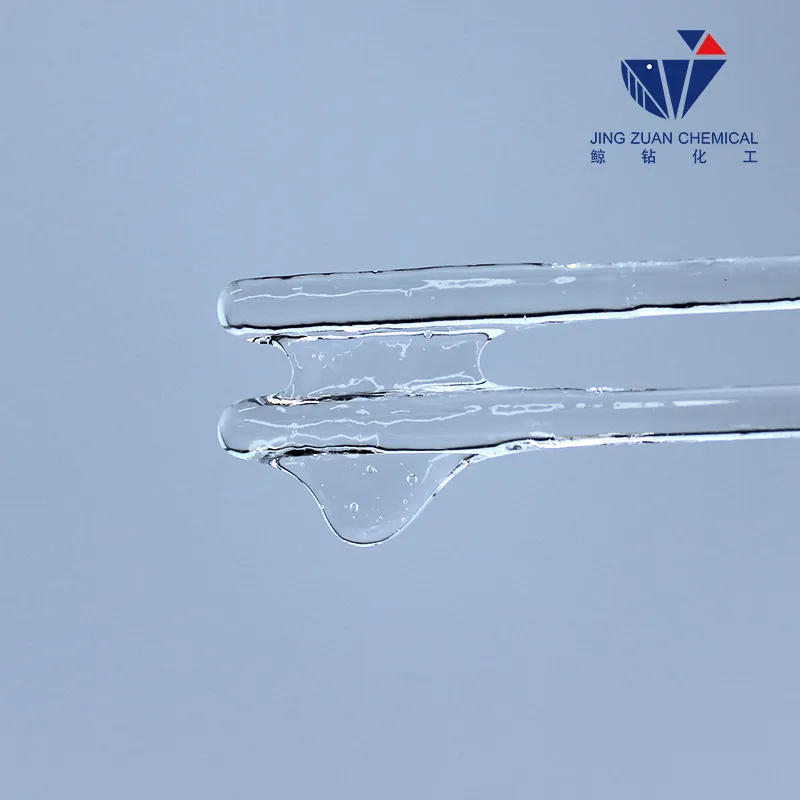

The role of Hydroxypropyl Methylcellulose (HPMC) in tile adhesive formulation is a topic of significant interest among industry experts and construction professionals. As a vital polymer used in tile adhesives, HPMC brings an impressive suite of properties that dramatically enhance both product performance and user experience.

From a trustworthiness perspective, considering the consistent performance of HPMC across various applications is crucial. Numerous industry studies and real-world tests corroborate its reliability in enhancing tile adhesive functions. Furthermore, HPMC is a non-toxic, non-irritant substance, adding safety to its long list of benefits. The material complies with globally recognized standards such as ISO and ASTM, assuring users of its credibility and performance integrity. Real-world experience highlights the impact of HPMC on project timelines and budgets. Projects employing HPMC-enhanced tile adhesives often see reduced labor costs due to easier handling and quicker installation times. This efficiency leads to significant time savings and profitability, a substantial advantage over traditional formulations that might require reworking or present challenges in tile alignment and adhesion. The environmental impact of construction materials is a growing concern, and HPMC addresses this by being biodegradable, offering an eco-friendly alternative without sacrificing utility. Its application aligns with sustainable building practices, fulfilling both performance requirements and environmental considerations—a dual benefit that is increasingly prioritized in modern construction methodologies. For those in the construction industry looking to optimize their tile adhesive solutions, integrating HPMC into formulations is a decision backed by substantial research and successful, widespread application. Its benefits resonate with the modern demands of efficiency, flexibility, and sustainability, providing an authoritative choice for enhancing construction quality and durability.

From a trustworthiness perspective, considering the consistent performance of HPMC across various applications is crucial. Numerous industry studies and real-world tests corroborate its reliability in enhancing tile adhesive functions. Furthermore, HPMC is a non-toxic, non-irritant substance, adding safety to its long list of benefits. The material complies with globally recognized standards such as ISO and ASTM, assuring users of its credibility and performance integrity. Real-world experience highlights the impact of HPMC on project timelines and budgets. Projects employing HPMC-enhanced tile adhesives often see reduced labor costs due to easier handling and quicker installation times. This efficiency leads to significant time savings and profitability, a substantial advantage over traditional formulations that might require reworking or present challenges in tile alignment and adhesion. The environmental impact of construction materials is a growing concern, and HPMC addresses this by being biodegradable, offering an eco-friendly alternative without sacrificing utility. Its application aligns with sustainable building practices, fulfilling both performance requirements and environmental considerations—a dual benefit that is increasingly prioritized in modern construction methodologies. For those in the construction industry looking to optimize their tile adhesive solutions, integrating HPMC into formulations is a decision backed by substantial research and successful, widespread application. Its benefits resonate with the modern demands of efficiency, flexibility, and sustainability, providing an authoritative choice for enhancing construction quality and durability.

Next:

Latest news

-

Why HPMC is a Key Additive in Wall Putty Formulations

NewsAug.05,2025

-

Redispersible Powder in Decorative Renders: Function Meets Finish

NewsAug.05,2025

-

Redispersible Powder for Interior Wall Putty: Smooth Results Every Time

NewsAug.05,2025

-

HPMC’s Water Retention Capacity in Dry Mortar Applications

NewsAug.05,2025

-

HPMC Factory Contributions to Liquid Detergents

NewsAug.05,2025

-

How HPMC Factory Products Change Detergent Textures

NewsAug.05,2025

Related PRODUCTS