Dec . 15, 2024 18:29 Back to list

Understanding the Production Process of Redispersible Polymer Powder for Various Applications

The Manufacturing Process of Redispersible Polymer Powder

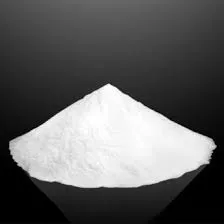

Redispersible polymer powder is a crucial ingredient in various industries, including construction, adhesives, paints, and coatings. Its primary function is to enhance the properties of the end products by improving adhesion, flexibility, and water resistance. The manufacturing process of redispersible polymer powder is complex and involves several steps, ensuring that the final product meets the required specifications. This article outlines the essential stages involved in the production of redispersible polymer powder.

1. Polymerization

The journey of redispersible polymer powder begins with the polymerization process. This stage involves the chemical reaction of monomers to form polymers. The most commonly used monomers in producing redispersible polymer powders are vinyl acetate, ethylene, and acrylics. The choice of monomers is crucial, as they determine the properties of the resulting polymer. The polymerization can be conducted through various methods, including emulsion, suspension, or solution polymerization. Emulsion polymerization is the most preferred method due to its efficiency in producing stable polymer emulsions with a controlled particle size.

2. Formation of Polymer Emulsion

Once the polymerization is complete, the resulting polymer chains are dispersed in water, creating a polymer emulsion. During this stage, surfactants and stabilizers are added to enhance the stability of the emulsion. The emulsion phase is critical because it allows the polymer to remain in a liquid state, facilitating its application in various formulations, such as tile adhesives and renders.

3. Spray Drying

To convert the polymer emulsion into a powder form, the next step is spray drying. This process involves atomizing the liquid emulsion into fine droplets which are then subjected to a hot air stream. As the droplets travel through the hot air, the water evaporates, leaving behind fine polymer particles. The spray drying process is crucial as it affects the particle size and morphology, which in turn influences the dispersibility and performance of the final product. Parameters such as inlet temperature, outlet temperature, and feed flow rate must be carefully controlled to achieve the desired powder characteristics.

redispersible polymer powder manufacturing process

The dried polymer powder may require milling and classification to achieve uniform particle size distribution. This step ensures that the powder can easily be dispersed in water when needed. The milling process breaks down any agglomerates, while classification separates fine particles from larger ones. The goal is to produce a powder that can redispersed in water to form a stable emulsion again, which is essential for its end-use applications.

5. Additive Incorporation

To enhance the performance of redispersible polymer powders, various additives may be included during the manufacturing process. These additives can improve properties such as flowability, shelf life, and processing characteristics. Common additives include anti-caking agents, stabilizers, and hydrophobizing agents, which help increase the water resistance of the final product.

6. Quality Control

Quality control is a critical aspect of the manufacturing process. Multiple tests are conducted to ensure that the redispersible polymer powder meets the specified standards. These tests may include assessments of particle size, moisture content, redispersibility in water, and performance in concrete or adhesive applications. By adhering to strict quality control measures, manufacturers can deliver high-quality products that meet customer expectations.

7. Packaging and Distribution

Once the redispersible polymer powder has passed all quality control tests, it is packaged for distribution. Bulk packaging options or smaller bags are available depending on customer needs. Proper packaging is essential to protect the powder from moisture and contamination during transportation and storage.

In conclusion, the manufacturing process of redispersible polymer powder involves several critical steps, from polymerization to quality control and packaging. Each phase plays a vital role in ensuring that the final product meets the specific requirements needed for various applications. As industries continue to evolve, so too will the processes and technologies used in the production of redispersible polymer powders, driving innovation and enhancing product performance.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025