Dez . 24, 2024 21:49 Back to list

rdp polymer

Understanding RDP Polymer A Breakthrough in Material Science

In recent years, the field of material science has witnessed significant advancements, particularly with the emergence of innovative polymers. Among these developments, RDP polymer (Redispersible Powder Polymer) stands out due to its versatility and varied applications. This article will explore the characteristics, production, and applications of RDP polymer, emphasizing its significance in modern materials.

What is RDP Polymer?

RDP polymer refers to a type of polymer that comes in the form of a redispersible powder. It is typically derived from vinyl acetate, ethylene, or other copolymers through a process that ensures it can be easily re-dispersed in water to form a stable solution. The ability to reconstitute the powder into a liquid state provides a wide range of applications, particularly in construction, adhesives, and coatings.

Characteristics of RDP Polymer

RDP polymers boast a myriad of advantageous properties that make them suitable for diverse applications. One paramount characteristic is their excellent adhesion properties, which enable strong bonding between materials. This is instrumental in construction applications where the integrity of mixed materials is crucial.

Additionally, RDP polymers exhibit good flexibility and elasticity, allowing them to withstand stress and deformation without losing their structural integrity. Furthermore, they display water resistance, antimicrobial properties, and enhanced durability, making them ideal for use in various environmental conditions.

Production Process

The production of RDP polymers involves several key processes. First, the raw materials are meticulously selected, usually involving a combination of different vinyl copolymers. These materials undergo a polymerization process that results in a viscous liquid. Once this polymer is formed, it is spray-dried or freeze-dried to create a powder form, where it retains its properties for extended periods.

rdp polymer

One of the critical aspects of producing RDP polymers is ensuring that the drying process does not affect the polymer's performance upon re-dispersal. Consequently, manufacturers utilize advanced techniques to maintain the quality and consistency of the final product.

Applications of RDP Polymer

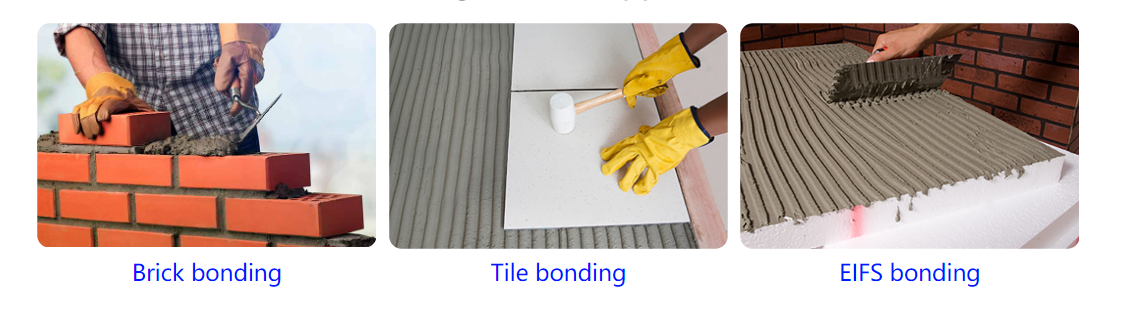

The versatility of RDP polymers enables their application in various industries. In the construction sector, RDP polymers are extensively used in dry-mix mortars, tile adhesives, and exterior insulation and finish systems (EIFS). Their exceptional adhesion and flexibility make them ideal for cement-based mixtures, allowing for improved workability and durability.

Moreover, RDP polymers are increasingly used in the production of paints and coatings. The addition of RDP enhances the performance of these products by improving adhesion to surfaces, resistance to weathering, and overall longevity. This makes RDP polymers a vital component in formulating water-based coatings that are both eco-friendly and effective.

In the realm of adhesives, RDP polymers contribute to the formulation of robust bond strength in various materials, including wood, ceramics, and plastics. They are particularly beneficial in formulations that require flexibility, allowing for movement without compromising the bond.

Environmental Impact and Sustainability

As industries strive for more sustainable solutions, RDP polymers have emerged as an eco-friendly alternative. Many manufacturers focus on developing water-based formulations that reduce the reliance on harmful solvents, making them safer for both the environment and human health. Additionally, the ability of RDP polymers to enhance the performance of building materials can lead to improved energy efficiency in structures, supporting global efforts towards sustainability.

Conclusion

RDP polymer is a remarkable innovation in material science, offering a combination of adhesion, flexibility, and durability that caters to various applications across numerous industries. As demand for sustainable and efficient materials continues to grow, the versatility and environmental benefits of RDP polymers position them as a critical component in the future of construction, coatings, and adhesives. Understanding and harnessing the potential of RDP polymers will undoubtedly pave the way for further advancements and innovations in material technology.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025