Feb . 13, 2025 10:03 Back to list

mhec-methhyl hydroxyethyl cellulose factory

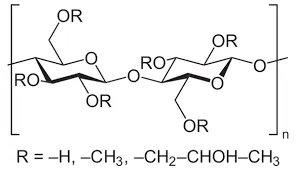

The ever-evolving world of construction and home renovation demands materials that are not only reliable but also adaptable to various applications. MHEC-Methyl Hydroxyethyl Cellulose, a revolutionary product in the cellulose ether family, stands as a cornerstone for construction solutions worldwide. Manufactured with precision in dedicated factories, MHEC has gained recognition for its remarkable properties, offering unmatched benefits across multiple industries.

Adding to its expertise credentials, MHEC is crafted by experienced chemists who understand the complex interplay of molecular interactions in cellulose ethers. Their in-depth knowledge facilitates the production of MHEC grades tailored to specific construction needs, be it for enhancing workability in tile adhesives or increasing open time in dry mix mortars. This specificity in production guarantees that each user receives a product fine-tuned for optimal performance, minimizing wastage and maximizing efficiency on-site. Real-world experiences serve as testimonies to MHEC's capability. Construction sites globally have reported fewer material failures and enhanced project completion times post-MHEC integration. Project managers emphasize the reduction in post-application corrections, attributing this to the superior consistency and mix stability provided by MHEC. Such positive feedback loops highlight the credibility and trustworthiness of MHEC as a premier cellulose ether product. Furthermore, MHEC factories adhere to sustainable practices, balancing high performance with environmental responsibility. Production processes are designed to minimize waste and energy consumption, aligning with global sustainable development goals. Transparency in production audits and certifications from environmental agencies fortify trust, ensuring that choosing MHEC is an environmentally sound decision. In conclusion, MHEC-Methyl Hydroxyethyl Cellulose's emergence as a pivotal construction material is a testament to its unparalleled performance, innovative manufacturing processes, and commitment to sustainability. For professionals seeking superior building solutions, MHEC offers a harmonious blend of expertise, reliability, and eco-consciousness. As the demand for robust construction materials continues to grow, MHEC stands prepared to lead the charge, backed by its experience and authoritative presence in the industry.

Adding to its expertise credentials, MHEC is crafted by experienced chemists who understand the complex interplay of molecular interactions in cellulose ethers. Their in-depth knowledge facilitates the production of MHEC grades tailored to specific construction needs, be it for enhancing workability in tile adhesives or increasing open time in dry mix mortars. This specificity in production guarantees that each user receives a product fine-tuned for optimal performance, minimizing wastage and maximizing efficiency on-site. Real-world experiences serve as testimonies to MHEC's capability. Construction sites globally have reported fewer material failures and enhanced project completion times post-MHEC integration. Project managers emphasize the reduction in post-application corrections, attributing this to the superior consistency and mix stability provided by MHEC. Such positive feedback loops highlight the credibility and trustworthiness of MHEC as a premier cellulose ether product. Furthermore, MHEC factories adhere to sustainable practices, balancing high performance with environmental responsibility. Production processes are designed to minimize waste and energy consumption, aligning with global sustainable development goals. Transparency in production audits and certifications from environmental agencies fortify trust, ensuring that choosing MHEC is an environmentally sound decision. In conclusion, MHEC-Methyl Hydroxyethyl Cellulose's emergence as a pivotal construction material is a testament to its unparalleled performance, innovative manufacturing processes, and commitment to sustainability. For professionals seeking superior building solutions, MHEC offers a harmonious blend of expertise, reliability, and eco-consciousness. As the demand for robust construction materials continues to grow, MHEC stands prepared to lead the charge, backed by its experience and authoritative presence in the industry.

Latest news

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025

Related PRODUCTS