Oct . 21, 2024 11:29 Back to list

HPMC Production Solutions from Leading Manufacturers for Diverse Applications

Understanding HPMC Manufacturers An Overview of Hydroxypropyl Methylcellulose

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether that has gained immense popularity across various industries, thanks to its unique properties and applications. As a product manufactured by specialized HPMC manufacturers, it is crucial to understand what HPMC is, the manufacturing process, and the industries it serves.

What is HPMC?

HPMC, a non-ionic polymer, is derived from natural cellulose. It is modified chemically to enhance its solubility and functionality. This white, powdery substance is soluble in cold water but creates a gel-like consistency. HPMC is known for its excellent thickening, emulsifying, and film-forming properties, making it a valuable ingredient in numerous applications.

The Manufacturing Process of HPMC

The production of HPMC involves several precise and carefully controlled steps

1. Cellulose Extraction The process begins with the extraction of cellulose from plant sources, typically wood pulp or cotton. This cellulose is the raw material needed to create HPMC.

2. Alkali Treatment The extracted cellulose undergoes an alkali treatment, which serves to swell and disperse the cellulose fibers. This step is crucial for facilitating further chemical modifications.

3. Etherification In this step, the alkali-treated cellulose is subjected to etherification using propylene oxide and methyl chloride. This reaction introduces hydroxypropyl and methyl groups to the cellulose backbone, resulting in HPMC. The ratio of these groups determines the specific properties of the final product.

4. Purification After etherification, the resulting HPMC is purified to remove any unreacted raw materials and by-products. This purification ensures that the product meets the stringent quality standards required by various industries.

5. Drying and Milling The purified HPMC is then dried and milled into a fine powder. This powder is the final product that will be packaged for distribution.

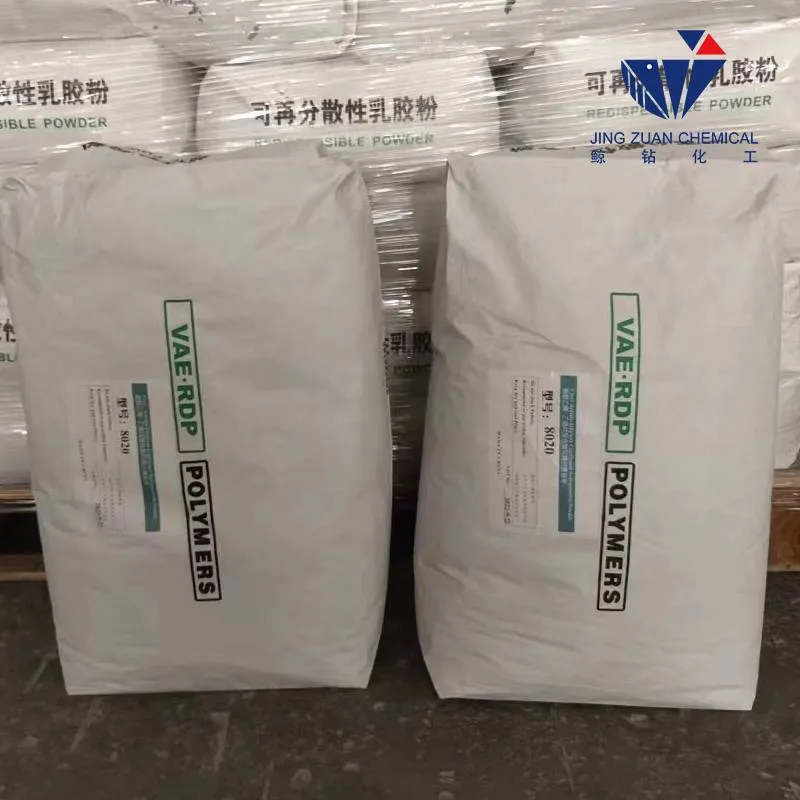

hpmc manufacturer

6. Quality Control Throughout the manufacturing process, rigorous quality control measures are implemented. Manufacturers conduct various tests to ensure the HPMC meets desired specifications, such as viscosity, solubility, and purity.

Applications of HPMC

Due to its unique characteristics, HPMC finds applications in a multitude of fields

1. Construction In the construction industry, HPMC is widely used as an additive in cement and gypsum-based products. Its ability to improve water retention, workability, and adhesion makes it essential for producing high-quality mortars, plasters, and tile adhesives.

2. Pharmaceuticals HPMC serves as an excipient in the pharmaceutical industry. It is employed as a thickening agent in syrups and as a binder in tablet formulations. Moreover, its controlled release properties make it valuable in developing sustained-release medication.

3. Food Industry HPMC is used in the food industry as a thickener, emulsifier, and stabilizer. It enhances the texture and stability of sauces, dressings, and dairy products, making it a popular choice among food manufacturers.

4. Personal Care Products In personal care and cosmetic products, HPMC acts as a thickening agent and stabilizer in lotions, creams, and shampoos. Its non-toxic nature and skin-friendly attributes make it suitable for use in a variety of formulations.

5. Paints and Coatings HPMC is also used in the paint industry to improve the viscosity and stability of paint formulations, making it easier to apply and providing better coverage.

Conclusion

As industries continue to evolve, the demand for versatile and effective materials like HPMC will only grow. HPMC manufacturers play a pivotal role in the production of this essential material, ensuring that it meets the rigorous standards required across various applications. By understanding the manufacturing process and the wide range of uses, one can appreciate the significance of HPMC in modern industry. Whether in construction, pharmaceuticals, food, or cosmetics, HPMC remains a critical ingredient that enhances product performance and quality. Through innovation and commitment to quality, HPMC manufacturers contribute substantially to the development of safer, more effective, and sustainable products.

-

The Widespread Application of Redispersible Powder in Construction and Building Materials

NewsMay.16,2025

-

The Widespread Application of Hpmc in the Detergent Industry

NewsMay.16,2025

-

The Main Applications of Hydroxyethyl Cellulose in Paints and Coatings

NewsMay.16,2025

-

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

NewsMay.16,2025

-

HPMC: Application as a thickener and excipient

NewsMay.16,2025

-

Hec Cellulose Cellulose: Multi functional dispersants and high-efficiency thickeners

NewsMay.16,2025