mar . 04, 2025 00:52 Back to list

hpmc types

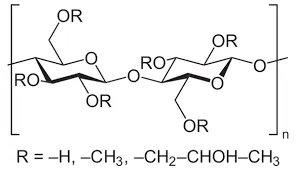

Hydroxypropyl methylcellulose (HPMC) stands as a versatile ingredient in various industrial applications, known for its role as a thickening agent, emulsifier, and film-forming polymer. It is pivotal in industries such as construction, pharmaceuticals, food production, and cosmetics. While many are familiar with HPMC as a general term, understanding its different types enhances its application specificity and efficacy across diverse sectors.

In the food industry, HPMC serves as a significant alternative to gelatin in vegetarian and vegan products. Its types enable the creation of capsules and coatings that cater to plant-based dietary preferences while maintaining the integrity and release profile required for effective nutrient delivery. Expert culinary developers and nutritionists appreciate the adaptability of HPMC types in creating textures and consistencies that enhance consumer experience without compromising on health or dietary specifications. Cosmetics benefit from the versatility of HPMC types as well. It acts as a film former, stabilizer, and thickener in products ranging from lotions to mascaras. The diverse molecular weights and substitution levels of HPMC variations allow cosmetic formulators to design products with the desired viscosity, texture, and moisture retention properties. Renowned cosmetic chemists often rely on specific HPMC types to achieve innovative textures that improve product feel and performance on the skin, thus building brand authority and trust among consumers. The selection of the appropriate HPMC type is not merely a technical decision but one rooted in a deep understanding of application needs and industry expertise. The distinct properties of each HPMC type cater to specific functional demands, ensuring that products not only meet regulatory standards but also achieve superior performance. As industries continue to evolve, the innovation and application knowledge around HPMC types remain critical to maintaining a competitive edge and building consumer trust through experience-backed expertise.

In the food industry, HPMC serves as a significant alternative to gelatin in vegetarian and vegan products. Its types enable the creation of capsules and coatings that cater to plant-based dietary preferences while maintaining the integrity and release profile required for effective nutrient delivery. Expert culinary developers and nutritionists appreciate the adaptability of HPMC types in creating textures and consistencies that enhance consumer experience without compromising on health or dietary specifications. Cosmetics benefit from the versatility of HPMC types as well. It acts as a film former, stabilizer, and thickener in products ranging from lotions to mascaras. The diverse molecular weights and substitution levels of HPMC variations allow cosmetic formulators to design products with the desired viscosity, texture, and moisture retention properties. Renowned cosmetic chemists often rely on specific HPMC types to achieve innovative textures that improve product feel and performance on the skin, thus building brand authority and trust among consumers. The selection of the appropriate HPMC type is not merely a technical decision but one rooted in a deep understanding of application needs and industry expertise. The distinct properties of each HPMC type cater to specific functional demands, ensuring that products not only meet regulatory standards but also achieve superior performance. As industries continue to evolve, the innovation and application knowledge around HPMC types remain critical to maintaining a competitive edge and building consumer trust through experience-backed expertise.

Next:

Latest news

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025

Related PRODUCTS