ਦਸੰ. . 07, 2024 08:39 Back to list

Understanding HPMC Varieties and Their Applications in Different Industries

HPMC Grades and Their Uses

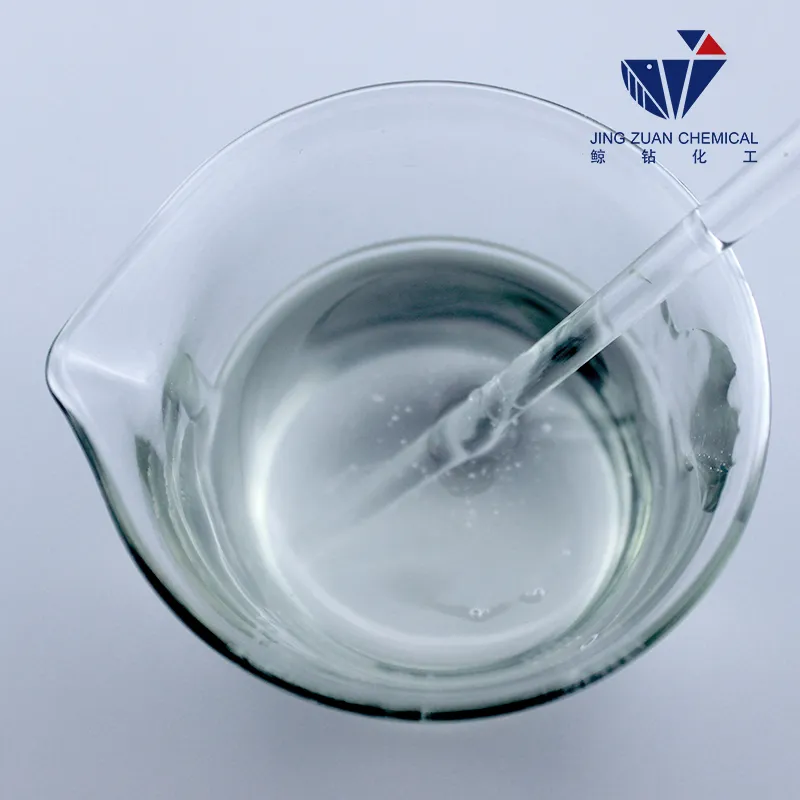

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether derived from natural cellulose and widely used in various industries due to its non-ionic nature, biocompatibility, and binding properties. HPMC is available in various grades, each tailored for specific applications, making it a crucial compound in pharmaceutical, food, cosmetic, and construction sectors. Understanding the different HPMC grades and their applications can help industries select the appropriate type for their specific needs.

Understanding HPMC Grades

HPMC grades are classified based on their viscosity, degree of substitution, and solubility in water. The viscosity of HPMC can range from low to high, influencing its behavior in various formulations. For instance, low-viscosity grades are ideal for applications requiring rapid dissolution, while high-viscosity grades provide enhanced thickening and gelling properties.

The degree of substitution refers to the average number of hydroxyl groups that have been replaced with hydroxypropyl and methoxy groups. This factor impacts the solubility and viscosity of HPMC in water. The higher the degree of substitution, the greater the solubility in cold water, leading to the formation of a clear solution. Conversely, lower degrees of substitution often result in solutions that are more viscous and gel-like.

Applications in Pharmaceuticals

In the pharmaceutical industry, HPMC is extensively used as an excipient in tablet formulation. It acts as a binder, film former, and controlled-release agent. Due to its unique properties, HPMC can improve the flow characteristics of powders and enhance the mechanical strength of tablets. Certain grades are specifically chosen for their ability to retain moisture and regulate drug release, making them indispensable for formulating extended-release medications. Additionally, HPMC is utilized in ophthalmic solutions to improve viscosity and stabilize formulations, ensuring better delivery of active ingredients to the eye.

Role in Food Industry

hpmc grades and uses

HPMC is utilized as a food additive, recognized for its thickening, emulsifying, and stabilizing properties. In the food industry, various grades of HPMC can modify the texture and enhance the mouthfeel of products like sauces, gravies, and dairy foods. It helps improve the shelf life of perishable products by acting as a moisture-retaining agent. Moreover, HPMC is popular in gluten-free baking, as it can mimic the binding properties of gluten, thus improving the elasticity and structure of baked goods.

Significance in Cosmetics

The cosmetic industry values HPMC for its thickening and film-forming abilities. It is found in a range of products, including creams, lotions, shampoos, and gels. HPMC enhances the stability and sensory characteristics of cosmetic formulations, offering a desirable texture that consumers appreciate. Its ability to create smooth films also aids in providing a protective barrier on the skin and hair, enhancing moisturization and overall product performance.

Construction Industry Uses

In the construction sector, HPMC serves as an essential additive in cement-based products. It functions as a water-retaining agent, improving workability and extending open time during application. HPMC modifications in dry mortars, tile adhesives, and plasters enhance the adhesion properties, ensuring better performance in construction applications. Additionally, HPMC's water retention capability prevents rapid drying, which is crucial for achieving optimal curing conditions.

Conclusion

HPMC, with its diverse grades, plays an integral role in multiple industries due to its multifaceted properties. From pharmaceuticals to food, cosmetics, and construction, HPMC provides tailored solutions that enhance the quality and performance of products. As industry demands evolve, ongoing research and development will likely lead to the discovery of new applications and formulations that take advantage of HPMC's unique characteristics, solidifying its position as a valuable ingredient across various sectors. Whether you are formulating tablets, creating gluten-free snacks, or developing cosmetic products, selecting the appropriate grade of HPMC is crucial for achieving the desired outcome.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025