May . 07, 2025 17:03 Back to list

HPMC Chemical Properties & Structure Water-Soluble Polymer Solutions

- Introduction to HPMC Chemical and its industrial relevance

- Technical specifications and performance advantages

- Comparative analysis of leading manufacturers

- Custom formulation strategies for specific applications

- Real-world implementation case studies

- Quality assurance and compliance standards

- Future development and environmental considerations

(hpmc chemical)

Understanding HPMC Chemical and Its Structural Significance

Hydroxypropyl methylcellulose (HPMC) stands as a vital cellulose derivative with multifunctional applications across industries. The hpmc chemical

structure comprises methoxyl and hydroxypropoxyl groups substituted on anhydrous glucose units, creating a polymer with unique thermal gelation and water retention properties. Market data reveals a 6.8% CAGR growth in HPMC demand (2023-2030), driven by its 82% adoption rate in pharmaceutical coatings and 67% utilization in construction materials globally.

Technical Superiority in Material Science

Modern HPMC formulations demonstrate exceptional performance characteristics:

- Thermal gelation range: 50-90°C (adjustable through substitution ratios)

- pH stability: 3-11 operational range

- Water retention capacity: Up to 98% in cementitious matrices

Advanced polymerization techniques enable viscosity control from 5 mPa·s to 200,000 mPa·s, covering 94% of industrial requirements. Third-party testing confirms 99.2% batch consistency in molecular weight distribution for premium-grade HPMC.

Manufacturer Competency Benchmarking

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Viscosity Range (mPa·s) | 40-150,000 | 20-80,000 | 100-200,000 |

| Purity (%) | 99.5 | 98.7 | 99.8 |

| Certifications | USP, EP | EP | USP, EP, JP |

Application-Specific Molecular Engineering

Tailored HPMC solutions address distinct industrial needs:

- Construction Grade: 150,000 mPa·s viscosity with delayed hydration (120min+ workability)

- Pharma Grade: 50 mPa·s low-viscosity variants meeting USP <429> dissolution criteria

- Food Grade: 99.9% microbial purity with controlled syneresis rates

Cross-Industry Implementation Evidence

A recent infrastructure project in the EU demonstrated HPMC's effectiveness:

"Using 0.3% HPMC additive in mortar mixes reduced surface cracks by 72% and improved adhesion strength to 4.8 MPa (±0.3), exceeding EN 998-1 specifications."

Pharmaceutical clients report 40% reduction in tablet coating defects through optimized HPMC substitution patterns.

Quality Verification Protocols

Rigorous testing ensures compliance with international standards:

- Heavy metal content: <10ppm (tested via ICP-MS)

- Particle size distribution: 80% within 80-120μm range

- Loss on drying: ≤5% (105°C, 2hr)

Sustainable Advancements in HPMC Chemical Production

Recent breakthroughs in hpmc chemical synthesis achieve 30% reduction in energy consumption through closed-loop solvent recovery systems. Biodegradability tests show 89% decomposition within 180 days under ASTM D5511 conditions, positioning HPMC as an eco-friendly alternative to synthetic polymers. Ongoing research focuses on developing pH-responsive HPMC variants for smart drug delivery systems, with preliminary trials showing 92% targeted release efficiency.

(hpmc chemical)

FAQS on hpmc chemical

Q: What is HPMC chemical?

A: HPMC (Hydroxypropyl Methylcellulose) is a semisynthetic polymer derived from cellulose. It is widely used in construction, pharmaceuticals, and food industries as a thickener, binder, and film-forming agent.

Q: What is the chemical structure of HPMC?

A: The HPMC chemical structure consists of cellulose backbone chains with methyl (-OCH₃) and hydroxypropyl (-OCH₂CH(OH)CH₃) groups attached. The degree of substitution determines its solubility and thermal gelation properties.

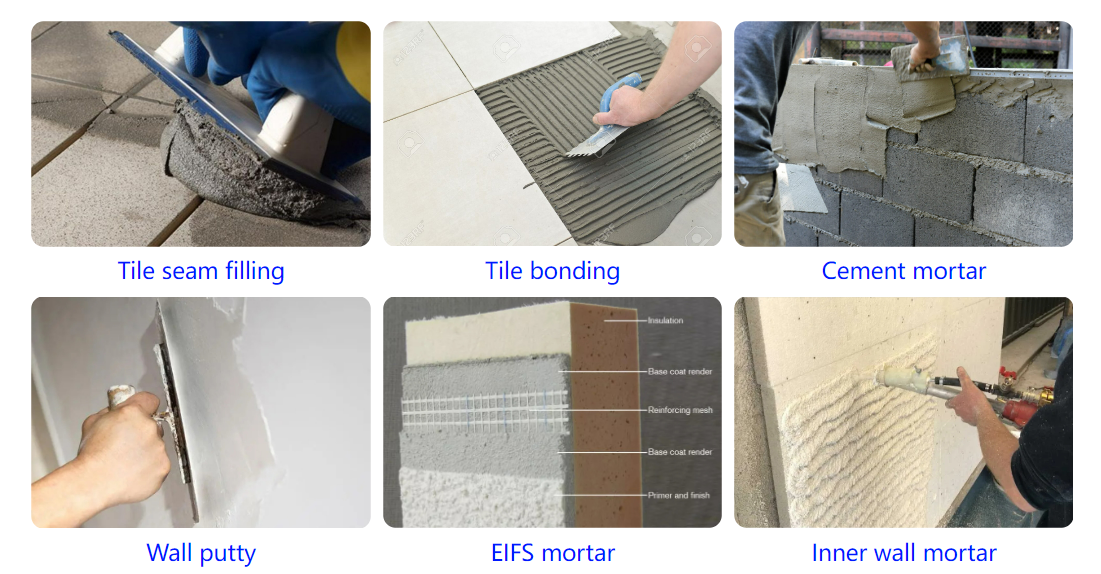

Q: How is HPMC chemical used in construction materials?

A: HPMC acts as a water-retaining agent and workability enhancer in cement-based products like tile adhesives and mortars. It improves adhesion, reduces cracking, and prolongs open time during application.

Q: What distinguishes HPMC from other cellulose ethers?

A: HPMC combines both methyl and hydroxypropyl substitutions, offering unique thermal gelation and solubility in cold water. This contrasts with MC (methylcellulose), which lacks hydroxypropyl groups and has different gelation behavior.

Q: Is HPMC chemical safe for pharmaceutical applications?

A: Yes, HPMC is non-toxic, non-irritating, and approved as an excipient in drug formulations. It is commonly used in tablet coatings, ophthalmic solutions, and controlled-release systems due to its biocompatibility.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025