jan . 17, 2025 02:32 Back to list

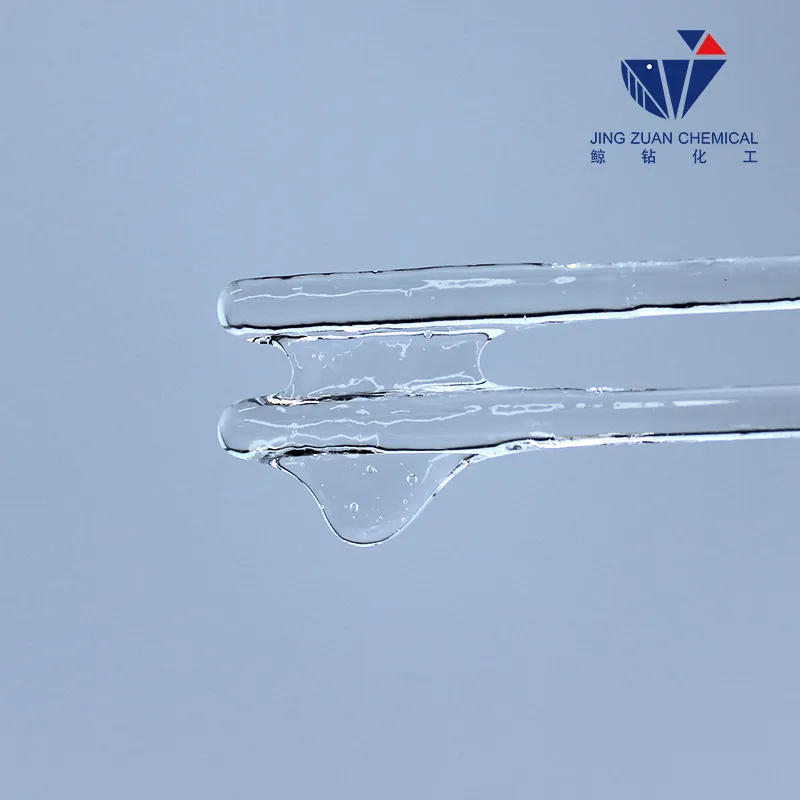

hydroxyethyl cellulose

5. Slow Addition to Water Gradually add HEC to the water with gentle stirring. This step is critical to avoid forming lumps. A vortex in the mixing vessel can be helpful to facilitate better dispersion. Use low-speed agitation to allow the polymer to swell properly. 6. Agitation and Dispersion Continue stirring the solution until the HEC is fully hydrated. The time required may vary based on the HEC grade and solution temperature but typically ranges from 30 minutes to 1 hour. High-shear mixing is not recommended as it may break down the polymer chains. 7. Check for Consistency Once dissolved, inspect the solution for consistency and transparency. A properly dissolved HEC solution should be free from undissolved particles and exhibit a uniform viscosity. 8. Adjust pH if Necessary The pH of the HEC solution should be monitored. For most applications, maintaining a pH of around 7 is optimal, although this can vary depending on specific end-use requirements. 9. Final Filtration To ensure a clean solution and remove any possible undissolved particles, pass the solution through a fine filter before use in formulation. This step is particularly important for applications requiring high purity and clarity. 10. Storage Considerations Store the dissolved HEC solution in a cool, dry place to prevent microbial growth and preserve viscosity. If storing for extended periods, include a preservative suited to the specific formulation environment. Common Mistakes and Troubleshooting - Clumping Indicates too swift an addition to the water. Always add HEC slowly. - Inconsistent Viscosity Can result from uneven mixing or the use of incorrect grade. Verify your formulation and mixing procedures. - Cloudy Solution This could be due to impurities in water or improper pH levels. Ensure water quality and pH adjustments are correct. Ensuring Success For professionals involved in product formulation, understanding the nuances of dissolving hydroxyethyl cellulose is essential. Proper technique enhances not only the quality of the final product but also its shelf-life and efficacy. Professionals should continually engage with suppliers for the latest advancements and tailored advice suited to specific applications, ensuring formulation success and product excellence. Leveraging these strategies will reinforce expertise, authority, and trustworthiness in producing top-tier products across various industries.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025