अक्ट . 01, 2024 00:33 Back to list

Enhancing Mortar Performance with Adhesive Additives for Improved Bonding Strength

The Importance of Mortar Adhesive Additives

In the construction and renovation industries, the quality of materials used directly impacts the integrity and durability of the structures we build. One of the often-overlooked components of this equation is the adhesive used in mortar mixtures. Mortar adhesive additives play a crucial role in enhancing the performance of traditional mortars, providing solutions for various challenges encountered on-site. This article examines the significance, types, and advantages of using mortar adhesive additives.

What are Mortar Adhesive Additives?

Mortar adhesive additives are substances incorporated into mortar mixtures to improve their properties. These additives can modify the strength, flexibility, water resistance, adhesion, and overall workability of the mortar. Commonly used in tile setting, bricklaying, and masonry, these additives ensure that the mortar adheres well to various surfaces, delivering better performance in demanding conditions.

Types of Mortar Adhesive Additives

1. Polymer-Based Additives These are often latex or acrylic emulsions added to the mortar mix to enhance adhesion and flexibility. They improve the tensile and flexural strength of the cured mortar, making it suitable for installations that may experience movement or thermal expansion.

2. Hydrophobic Additives These additives are designed to repel water, enhancing the water resistance of the mortar. They are particularly important in areas exposed to moisture, such as bathrooms, kitchens, and exterior applications. By preventing water ingress, these additives help reduce the risk of mold and mildew growth.

3. Retarding Agents Used to slow down the setting process of mortar, retarding agents are crucial in hot weather conditions. They provide masons with more working time, allowing for better placement and finishing of the mortar before it hardens.

4. Accelerators In contrast, accelerators are used to speed up the curing process. This is particularly beneficial when working in cooler temperatures or when quick repairs are needed. By facilitating faster set times, these additives can help ensure project timelines are met.

5. Mineral Additives These include materials such as silica fume, fly ash, or volcanic ash. They can enhance the mechanical properties of mortar, improve workability, and increase resistance to chemical attacks.

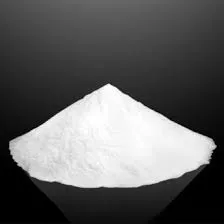

mortar adhesive additive

Advantages of Using Mortar Adhesive Additives

The inclusion of mortar adhesive additives in construction projects brings numerous benefits

- Enhanced Adhesion Additives improve the bond strength between the mortar and the surfaces it adheres to. This is essential for preventing failures in applications like tile installations or external cladding.

- Increased Durability Mortars with additives exhibit greater resistance to weathering, chemical exposure, and thermal cycling. This prolongs the lifespan of structures, making them more reliable over time.

- Improved Workability Many additives enhance the workability of the mortar, making it easier to mix, spread, and finish. This can lead to better aesthetic results and efficiency on the job site.

- Versatility Using the right combination of additives allows for customized solutions tailored to specific environmental and application requirements. This flexibility is invaluable for architects and builders.

- Cost Effectiveness Though some additives may increase initial material costs, the long-term benefits often outweigh these expenses. Reduced maintenance needs and extended durability lead to overall cost savings.

Conclusion

In conclusion, mortar adhesive additives are vital components in modern construction practices. They enhance the performance of mortar through improved adhesion, flexibility, and durability. With various types of additives available, builders and contractors can select the appropriate ones to meet the unique challenges of each project. As the industry continues to evolve, the use of these additives will likely become even more prevalent, underpinning the quality and longevity of our built environments. By investing in better mortar formulations, we are ultimately investing in safer, more resilient structures for future generations.

-

The Widespread Application of Redispersible Powder in Construction and Building Materials

NewsMay.16,2025

-

The Widespread Application of Hpmc in the Detergent Industry

NewsMay.16,2025

-

The Main Applications of Hydroxyethyl Cellulose in Paints and Coatings

NewsMay.16,2025

-

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

NewsMay.16,2025

-

HPMC: Application as a thickener and excipient

NewsMay.16,2025

-

Hec Cellulose Cellulose: Multi functional dispersants and high-efficiency thickeners

NewsMay.16,2025