सेप . 21, 2024 10:54 Back to list

hpmc viscosity grades

Understanding HPMC Viscosity Grades

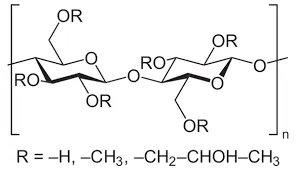

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used polymer in various industries, including food, pharmaceuticals, and construction. One of the essential characteristics of HPMC is its viscosity, which is influenced by its molecular weight and the degree of substitution. This article aims to explain the significance of HPMC viscosity grades and their applications.

Understanding HPMC Viscosity Grades

The viscosity of HPMC affects its performance in applications. For instance, low viscosity grades are often utilized in applications requiring quick dispersion and minimal thickening properties. They are commonly found in dry mix mortars, where ease of mixing is essential. On the other hand, high viscosity grades are employed in formulations that require significant thickening and gel-forming capabilities. These higher viscosity grades are ideal for creating stable suspensions and emulsions, particularly in the pharmaceutical and cosmetic industries.

hpmc viscosity grades

In the pharmaceutical field, HPMC serves as a critical excipient in drug formulations. It acts as a binder in tablets and as a thickening agent in various liquid formats. The viscosity grade chosen can directly affect the release profile of the drug, impacting its bioavailability. For immediate-release formulations, lower viscosity grades are preferred, while high viscosity grades are often used in controlled-release applications to ensure that the drug is released over an extended period.

In the construction industry, HPMC's role is equally important. It is commonly used in tile adhesives and joint compounds. The viscosity of the HPMC determines the workability and performance of these products. For tile adhesives, a medium viscosity grade allows for easy application and sag resistance, ensuring that tiles remain in place during installation. In contrast, higher viscosity grades are used in thicker compounds that require stronger adhesion and increased water retention.

Food applications also benefit from various HPMC viscosity grades. It is commonly incorporated into emulsions, sauces, and dressings, where it aids in stabilizing the texture and consistency. Different viscosity grades can tailor the mouthfeel and flow behavior of food products, enhancing consumer experience.

In summary, the viscosity grades of HPMC are crucial in determining its functionality across various industries. By understanding these grades, manufacturers can select the appropriate type of HPMC for their specific needs, ensuring optimal performance in their applications. Whether in pharmaceuticals, food products, or construction materials, the right viscosity grade of HPMC plays a pivotal role in product quality and effectiveness.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025