नोभ . 19, 2024 08:43 Back to list

HPMC Production Facility for Hydroxypropyl Methyl Cellulose Manufacturing Processes and Innovations

The HPMC Production A Closer Look at Hydroxypropyl Methyl Cellulose Manufacturing

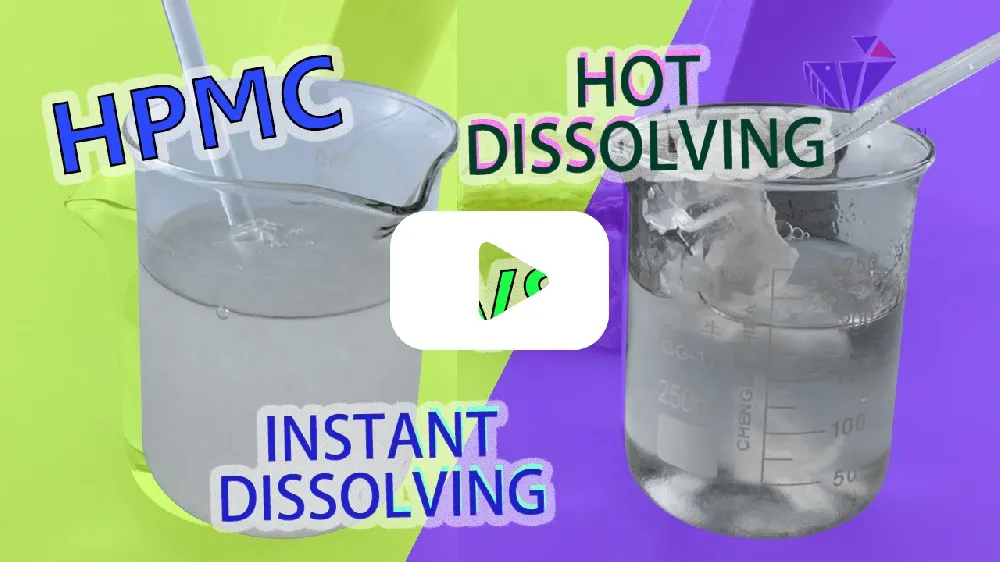

Hydroxypropyl Methyl Cellulose (HPMC) is a versatile cellulose ether widely utilized across numerous industries due to its unique properties. Known for its ability to form films, enhance viscosity, and act as a stabilizer, HPMC finds applications in pharmaceuticals, construction, food, and personal care products. Understanding the manufacturing process of HPMC can illuminate why it is such a sought-after product in contemporary markets.

The HPMC Production A Closer Look at Hydroxypropyl Methyl Cellulose Manufacturing

Once the cellulose is transformed, the next step involves the formation of HPMC powder. The modified cellulose is dissolved in water, creating a viscous solution that is carefully dried, often using spray drying or drum drying techniques. This process ensures that the final product retains the desired properties while preventing degradation. The resultant HPMC granules can then be sieved to achieve specific particle sizes, catering to different industrial requirements.

hpmc-hydroxypropyl methyl cellulose factory

Quality control is a critical component of HPMC manufacturing. Throughout the production process, stringent quality checks are implemented to ensure that the HPMC meets industry standards. Parameters such as viscosity, solubility, and purity are meticulously analyzed. Manufacturers often employ advanced analytical techniques to monitor these properties, ensuring that the HPMC produced is consistent and reliable for use.

Furthermore, sustainability is becoming increasingly important in HPMC production. Manufacturers are now exploring environmentally friendly practices, including the use of renewable resources and efficient waste management systems. The goal is to reduce the ecological footprint of HPMC production while still meeting market demand.

In summary, the manufacture of Hydroxypropyl Methyl Cellulose is a sophisticated yet fascinating process intertwining chemistry, engineering, and sustainability. As industries continue to innovate, the demand for HPMC is expected to grow, driven by its multifunctional properties. Understanding the factory processes behind HPMC production not only highlights its value in various applications but also underscores the importance of quality and sustainability in manufacturing. As we look to the future, the advancements in HPMC production will undoubtedly play a critical role in enhancing the efficiency and performance of countless products we use every day.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025