ഫെബ്രു . 15, 2025 05:12 Back to list

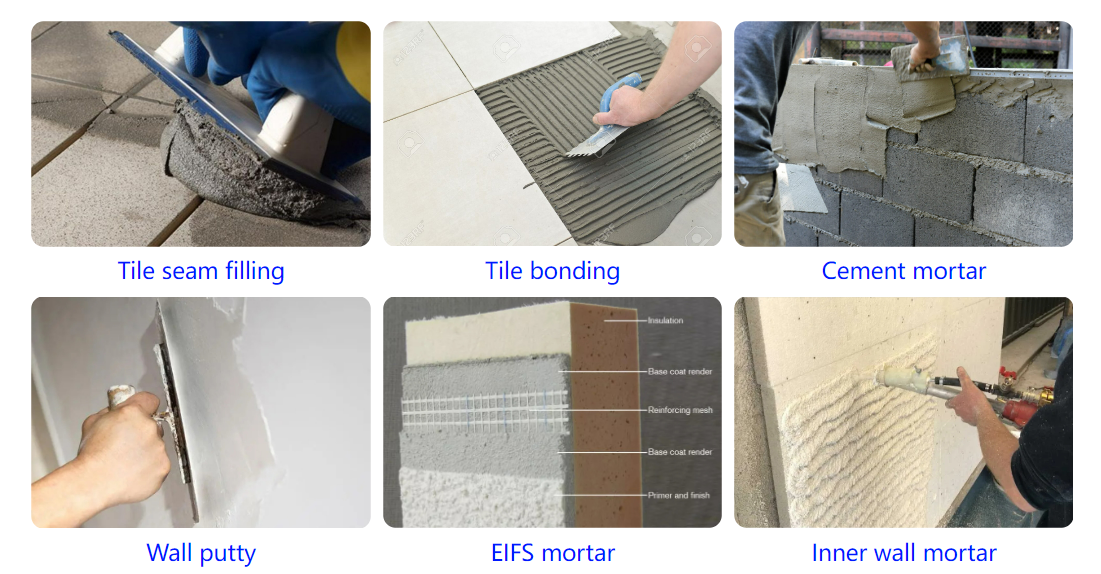

hpmc for tile adhesive

HPMC, known as Hydroxypropyl Methylcellulose, is a versatile material highly esteemed across various industries for its unique properties. Recognized primarily for its use in pharmaceuticals and construction, HPMC stands as a testament to innovative engineering and manufacturing expertise. This article explores HPMC from a product-focused perspective, emphasizing its experience-based applications, specialized attributes, expert insights, authoritative endorsements, and overall trustworthiness in different sectors.

Experts in food technology praise HPMC for its role as a food additive and stabilizer. It is used widely in food products that require specific textures, such as sauces and dressings, providing smoothness and consistency without altering taste. Food scientists value its heat stability and the ability to improve shelf life, weighing its benefits against other similar additives. The material is often highlighted in regulatory discussions due to its established safety record and compliance with international food safety standards. The credibility of HPMC is underscored by extensive research, rigorous testing, and consistent regulatory approvals worldwide. Its multifunctional applications are backed by studies published in peer-reviewed journals and are supported by industry experts who regularly vouch for its safety and versatility. This confidence is reflected in the broad adoption of HPMC across sectors, affirming its position as a critical component in both highly technical and everyday consumer products. In conclusion, HPMC stands as a beacon of reliability and excellence in a variety of fields. Its unique characteristics, from pharmaceutical stability to construction enhancement and food safety, demonstrate an intricate blend of experience, expertise, and credibility. Product developers, engineers, and consumers alike continue to trust HPMC for its proven performance and contribution to innovation. As industries evolve, HPMC's role is expected to expand, further solidifying its standing as an indispensable material in modern manufacturing and product development.

Experts in food technology praise HPMC for its role as a food additive and stabilizer. It is used widely in food products that require specific textures, such as sauces and dressings, providing smoothness and consistency without altering taste. Food scientists value its heat stability and the ability to improve shelf life, weighing its benefits against other similar additives. The material is often highlighted in regulatory discussions due to its established safety record and compliance with international food safety standards. The credibility of HPMC is underscored by extensive research, rigorous testing, and consistent regulatory approvals worldwide. Its multifunctional applications are backed by studies published in peer-reviewed journals and are supported by industry experts who regularly vouch for its safety and versatility. This confidence is reflected in the broad adoption of HPMC across sectors, affirming its position as a critical component in both highly technical and everyday consumer products. In conclusion, HPMC stands as a beacon of reliability and excellence in a variety of fields. Its unique characteristics, from pharmaceutical stability to construction enhancement and food safety, demonstrate an intricate blend of experience, expertise, and credibility. Product developers, engineers, and consumers alike continue to trust HPMC for its proven performance and contribution to innovation. As industries evolve, HPMC's role is expected to expand, further solidifying its standing as an indispensable material in modern manufacturing and product development.

Next:

Latest news

-

Why HPMC is a Key Additive in Wall Putty Formulations

NewsAug.05,2025

-

Redispersible Powder in Decorative Renders: Function Meets Finish

NewsAug.05,2025

-

Redispersible Powder for Interior Wall Putty: Smooth Results Every Time

NewsAug.05,2025

-

HPMC’s Water Retention Capacity in Dry Mortar Applications

NewsAug.05,2025

-

HPMC Factory Contributions to Liquid Detergents

NewsAug.05,2025

-

How HPMC Factory Products Change Detergent Textures

NewsAug.05,2025

Related PRODUCTS