Дек . 29, 2024 12:26 Back to list

rdp polymer

Understanding RDP Polymer Innovations in Polymer Science

The field of polymer science has witnessed remarkable advancements over the past few decades, leading to the development of various innovative materials. Among these, RDP (Redispersible Polymer Powder) has emerged as a crucial element in the industry, particularly in construction, coatings, adhesives, and sealants. With its unique properties and versatile applications, RDP polymer is revolutionizing how materials are formulated and utilized across various sectors.

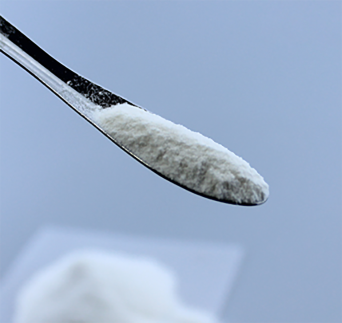

RDP is a type of polymer that is primarily designed to improve the performance characteristics of cement-based mixtures. It is typically produced as a powder that can be easily redispersed in water, forming a stable emulsion. This property allows RDP to be incorporated into dry mix products, providing enhanced performance when the materials are mixed with water on-site. This is especially beneficial in construction applications where conditions may not always be conducive to using liquid polymers.

One of the primary advantages of RDP polymer is its ability to enhance the mechanical properties of the final product. When added to cement mortars and other composites, RDP can significantly improve adhesion, flexibility, and durability. This performance enhancement is critical, particularly in applications where resistance to cracking and shrinkage is essential. For instance, in tile adhesives, RDP allows for better bonding to both the tile and substrate surfaces, ensuring long-lasting installations.

Moreover, RDP polymers contribute to the workability of the mixtures. They can help in achieving a smoother and more consistent application, which is vital for ensuring high-quality finishes in construction and renovations. The improved rheological properties offered by RDP enable contractors to apply products more easily, reducing labor time and costs associated with installation.

rdp polymer

In addition to mechanical benefits, RDP polymers also improve the resistance of cement-based products to environmental factors. For example, when used in exterior applications, RDP can enhance the resistance of the mix to water, freeze-thaw cycles, and other climatic challenges. This characteristic is increasingly important as the construction industry faces the challenges of climate change and the need for more durable and sustainable materials.

From a production standpoint, the incorporation of RDP polymers into dry mix formulations simplifies the manufacturing process. By using dry powder, manufacturers can streamline their production lines, reducing the need for complex liquid handling systems. This not only lowers costs but also minimizes waste associated with excess materials. Furthermore, the redispersible nature of RDP allows for flexibility in formulations, enabling manufacturers to tailor products to meet specific performance requirements.

As the demand for eco-friendly and sustainable building materials continues to rise, RDP polymers have also adapted to meet these environmental considerations. Many RDP types are now being developed with renewable raw materials, contributing to a lower carbon footprint in construction projects. Additionally, their performance enhancements can lead to reduced maintenance needs and longer service life for buildings, further aligning with sustainable building practices.

In conclusion, RDP polymers represent a significant advancement in the field of polymer science, with a wide range of applications that enhance the performance of construction materials. Their ability to improve mechanical properties, workability, and environmental resistance makes them indispensable in modern construction practices. As research and development in polymer technology continue, we can anticipate even more innovative applications of RDP polymers, shaping the future of material science and construction methodologies. By embracing these advancements, the industry can continue to evolve towards more efficient, durable, and sustainable building solutions.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025

-

The Ultimate Guide to Mortar Bonding Agent

NewsAug.06,2025