Јан . 02, 2025 08:23 Back to list

hydroxyethyl cellulose manufacturing process

The Manufacturing Process of Hydroxyethyl Cellulose

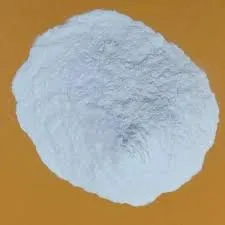

Hydroxyethyl cellulose (HEC) is a non-ionic water-soluble polymer derived from cellulose, widely used in various industries, including pharmaceuticals, cosmetics, and construction. Its unique properties, such as thickening, film-forming, and gelling capabilities, make it an essential ingredient in numerous applications. The manufacturing process of hydroxyethyl cellulose involves several critical steps cellulose sourcing, etherification, purification, and drying. In this article, we will explore each stage of the HEC manufacturing process in detail.

1. Cellulose Sourcing

The production of hydroxyethyl cellulose begins with the extraction of cellulose, the primary raw material. Cellulose is abundantly available in plant materials, particularly in cotton and wood pulp. The chosen cellulose source undergoes a series of treatments to remove impurities, such as lignin, hemicellulose, and other contaminants. This step is crucial, as the purity of cellulose significantly influences the quality of the final HEC product.

2. Etherification

The next stage is the chemical modification process known as etherification. In this step, the purified cellulose is reacted with ethylene oxide in the presence of a catalyst, typically an alkaline substance. The reaction occurs in a controlled environment where conditions such as temperature and pressure are optimized to enhance the yield and quality of hydroxyethyl cellulose. Ethylene oxide reacts with the hydroxyl groups of cellulose, resulting in the substitution of hydroxyethyl groups, thereby transforming cellulose into hydroxyethyl cellulose.

The etherification process is critical, as it dictates the degree of substitution (DS) of the HEC product. The DS influences HEC's solubility, viscosity, and other rheological properties. Manufacturers aim for a precise DS to develop HEC products that meet specific performance criteria for various applications.

3

. Purificationhydroxyethyl cellulose manufacturing process

Following etherification, the reaction mixture typically contains unreacted ethylene oxide, catalyst residues, and by-products that must be removed to obtain pure hydroxyethyl cellulose. Purification is usually conducted through a series of washing and filtration steps. The HEC is dissolved in water and subjected to precipitation and sedimentation processes. This helps in separating the HEC from the impurities based on solubility differences.

In some cases, alcohol is used to precipitate the hydroxyethyl cellulose from the aqueous solution, resulting in a purer form. The end of the purification process yields a concentrated HEC solution, which is further treated to enhance purity and performance.

4. Drying

The final step in the manufacturing process is drying the purified hydroxyethyl cellulose to achieve a powder form suitable for storage and transportation. Various drying methods could be employed, including spray drying, freeze drying, or drum drying, depending on the desired characteristics of the final product.

Proper drying is essential as it ensures that the moisture content is controlled, which is vital for maintaining the stability and shelf-life of the HEC product. Once the drying process is complete, the HEC is milled to achieve the desired particle size distribution, making it suitable for diverse formulations.

Conclusion

The manufacturing process of hydroxyethyl cellulose is a complex, multi-stage procedure that requires attention to detail, from sourcing high-quality cellulose to ensuring efficient etherification, effective purification, and proper drying. The resulting hydroxyethyl cellulose has become a vital ingredient in various industries due to its versatility and functionality. Understanding the manufacturing process is crucial for manufacturers seeking to optimize production and improve the quality of HEC for their specific applications. With ongoing research and development, the properties and functionalities of hydroxyethyl cellulose continue to evolve, enhancing its utility in the marketplace.

-

tile-bonding-additives-for-stronger-bonds

NewsAug.22,2025

-

construction-grade-rdp-for-wholesale-needs

NewsAug.22,2025

-

trusted-wholesale-hec-partners

NewsAug.22,2025

-

hec-solutions-for-industrial-excellence

NewsAug.22,2025

-

construction-additives-need-hpmc-essentials

NewsAug.22,2025

-

hpmc-versatile-cellulose-ether-for-industries

NewsAug.22,2025