May . 31, 2025 14:06 Back to list

China HPMC Manufacturer High-Quality Hydroxypropyl Methyl Cellulose Supplier

This comprehensive guide explores China's HPMC industry through these key perspectives:

- Global HPMC market data and production statistics

- Technical specifications and performance advantages

- Comparative analysis of leading manufacturers

- Custom formulation development processes

- Industry-specific application case studies

- Quality assurance and certification standards

- Future trends in cellulose ether technology

(china hpmc-hydroxypropyl methyl cellulose)

China's Dominance in Global HPMC Production and Supply

China currently manufactures over 65% of the world's hydroxypropyl methyl cellulose, producing approximately 350,000 metric tons annually according to the Global Construction Chemicals Association. Three industrial clusters in Shandong, Hebei, and Henan provinces have established vertically integrated facilities capable of handling entire production chains from wood pulp processing to final packaging. Chinese HPMC suppliers command nearly 48% of global exports, with shipments increasing at a compound annual growth rate of 8.2% since 2018. The country's advanced etherification technology enables manufacturers to precisely control substitution levels between 19-30% for methoxy groups and 4-12% for hydroxypropoxy groups, allowing production of over 20 specialized grades meeting international pharmacopoeia standards including USP, EP, and JP compliance.

Technical Superiority of Modern HPMC Manufacturing

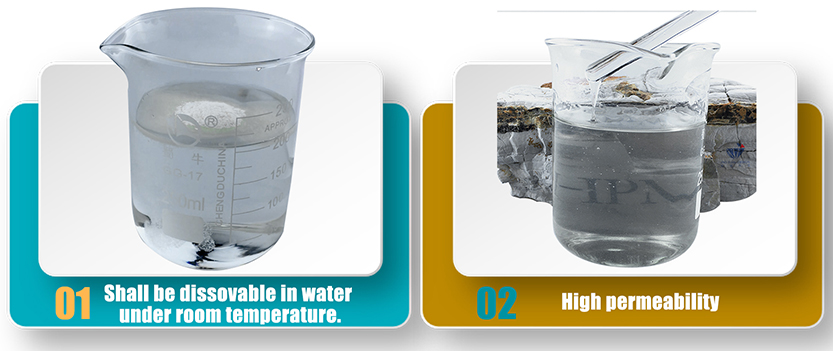

Premium-grade HPMC from China achieves viscosity consistency within ±10% deviation through continuous reactor technology that maintains reaction temperatures of 50-90°C within ±2°C tolerance. Advanced substitution control creates targeted gel points ranging from 50-90°C with 5,000-200,000 mPa·s viscosity across product grades. These cellulose ethers demonstrate superior water retention exceeding 95% in cementitious applications, verified through ASTM C150 testing protocols. Third-party laboratory analysis confirms particle size distribution averaging 80-100μm with particle uniformity exceeding 90% consistency. Automated purification systems reduce chloride content below 100ppm and achieve >99.5% sodium chloride removal through proprietary membrane filtration techniques. Recent innovations include 30-minute delayed dissolution types for construction applications and low-ash pharmaceutical grades containing less than 0.5% residue.

Comparative Analysis of Leading Chinese HPMC Manufacturers

| Manufacturer | Production Capacity | Certifications | Viscosity Range | Key Markets | Customization |

|---|---|---|---|---|---|

| Shandong Manufacturer A | 80,000 tons/year | ISO 9001, ISO 14001, FDA, Halal | 5-200,000 mPa·s | Construction (52%), Pharma (30%) | 200+ formulations |

| Jiangsu Manufacturer B | 60,000 tons/year | ISO 9001, KOSHER, REACH | 50-150,000 mPa·s | Pharma (45%), Food (25%) | Grade-specific modifications |

| Hebei Manufacturer C | 45,000 tons/year | ISO 9001, BRC, GMP | 400-100,000 mPa·s | Construction (78%), Paint (15%) | Retardation time customization |

Application-Tailored HPMC Formulation Development

Leading Chinese HPMC manufacturers employ formulation optimization processes that typically proceed through these stages:

- Requirement Analysis: Technical specialists conduct client interviews to document specific functionality requirements such as dissolution rates and compatibility with other formulation components.

- Bench Development: Researchers prepare 5-15 iterations altering substitution ratios (MS/DS), polymerization degrees, and particle size distributions before comprehensive performance evaluation.

- Performance Testing: Minimum 8-parameter verification including gel point determination (ASTM D7865), water retention (ASTM C1506), and film formation capability analysis.

- Pilot Production: Facilities capable of generating 500kg batches conduct process optimization for full-scale manufacturing.

A North American paint manufacturer recently developed a custom HPMC grade achieving 15% opacity enhancement through modification of cellulose molecular weight distribution. Similarly, a European pharmaceutical company reduced tablet disintegration time by 40 seconds by optimizing hydroxypropoxy group substitution levels during development.

Documented Performance in Major Construction Projects

The Burj Khalifa construction utilized 350 tons of specialized Chinese HPMC to enhance mortar workability while maintaining compressive strength specifications at ambient temperatures exceeding 45°C. During Singapore's Thomson-East Coast MRT project, modified HPMC batches achieved 92% water retention in tunnel lining applications despite 90% humidity conditions. Quality testing demonstrated 94% viscosity retention after 60 minutes mixing, exceeding JIS A6909 standards for tile adhesives. These specifications originated from three years of collaborative development between the construction firm and their HPMC supplier. Construction projects utilizing Chinese HPMC document material cost reductions between 12-18% compared to alternative formulations while maintaining required performance parameters.

Quality Assurance Protocols in HPMC Manufacturing

Premium manufacturers implement eight-stage quality assurance including gas chromatography validation of substitution levels (±0.5 accuracy), particle distribution analysis using laser diffraction technology, and microbial testing compliant with USP <61> and <62> standards. Raw materials undergo 20-point inspection before acceptance, with cellulose purity verified through ISO 5351 methods. Automated process controls monitor 14 critical parameters including reaction vessel pressure (±0.5 bar) and nitrogen flow rates during alkalization. Finished goods testing requires confirmation for eight specification points using calibrated instruments with documented calibration traceability to national standards. All production facilities maintain current GMP certification with documentation systems compliant with ISO 9001 requirements.

Partnering with China HPMC Manufacturers for Sustainable Supply Chains

The trajectory of China's hydroxypropyl methyl cellulose industry points toward increased molecular precision engineering and expanded production efficiency. Major manufacturers currently invest an average of 8.5% of revenue into R&D focused on product categories such as:

- Thermo-reversible HPMC for pharmaceutical controlled release applications

- Low-dusting surface-treated grades improving workplace safety

- Salinity-resistant formulations for construction applications in harsh environments

Environmental innovations demonstrate significant progress as well, with advanced solvent recovery systems reducing emissions to below 0.8% during production. Forward-thinking partnerships between suppliers and international clients leverage these technological advancements, developing formulations meeting both sustainability goals and technical requirements. The documented performance advantages of Chinese HPMC cement its position within global industrial supply networks.

(china hpmc-hydroxypropyl methyl cellulose)

FAQS on china hpmc-hydroxypropyl methyl cellulose

Q: What is HPMC-Hydroxypropyl Methyl Cellulose used for?

A: HPMC is a cellulose ether widely used as a thickener, binder, and film-former in construction materials, pharmaceuticals, and food. It improves water retention and workability in cement-based products. Chinese manufacturers produce high-purity HPMC for global industries.

Q: How to choose a reliable China HPMC-Hydroxypropyl Methyl Cellulose supplier?

A: Look for suppliers with ISO certifications, proven production capacity, and positive client reviews. Reliable Chinese suppliers offer customized viscosity grades and technical support. Ensure they comply with international quality standards like USP or EU pharmacopeia.

Q: What industries benefit from China-sourced HPMC?

A: Key industries include construction (tile adhesives, renders), paints, pharmaceuticals (tablet coatings), and personal care products. Chinese HPMC manufacturers tailor products to meet sector-specific requirements like solubility or thermal gelation.

Q: Why is China a leading HPMC-Hydroxypropyl Methyl Cellulose manufacturer?

A: China combines advanced production technology with cost-effective raw material sourcing. Leading manufacturers invest in R&D for customized solutions. Strict environmental regulations ensure sustainable and consistent product quality.

Q: What quality control measures do Chinese HPMC suppliers implement?

A: Reputable suppliers conduct batch-wise testing for viscosity, moisture content, and particle size. They use HPLC and spectrophotometry for purity verification. Many provide COA (Certificate of Analysis) and traceability systems for each shipment.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025