Okt . 11, 2024 07:09 Back to list

hpmc-hydroxypropyl methyl cellulose factory

The HPMC (Hydroxypropyl Methyl Cellulose) Factory Innovations in Production

Hydroxypropyl Methyl Cellulose (HPMC) is a non-ionic cellulose ether that has gained immense popularity across various industries, primarily due to its versatile properties. As a leading manufacturer in the field, our HPMC factory employs cutting-edge technologies and sustainable practices to produce high-quality HPMC that meets the diverse needs of our global clientele.

Understanding HPMC

HPMC is derived from cellulose, a natural polymer obtained from plant cell walls. By chemically modifying cellulose, HPMC is created, which imparts unique characteristics such as water solubility, thickening abilities, and adhesive properties. This makes HPMC an essential ingredient in a myriad of applications, including pharmaceuticals, food products, construction materials, personal care products, and cosmetics.

State-of-the-art Manufacturing Process

Our HPMC factory utilizes a state-of-the-art manufacturing process that ensures the highest quality product. The production begins with sourcing high-purity cellulose, which is then subjected to a series of chemical modifications. Through this careful and controlled process, the desired degree of hydroxypropyl substitution and methyl substitution is achieved, resulting in various grades of HPMC tailored for specific applications.

The factory is equipped with advanced machinery and technology that optimize the synthesis process, minimize waste, and enhance efficiency. Continuous monitoring of parameters such as temperature, pH, and reaction time ensures consistency in the final product. Additionally, our manufacturing facility adheres to stringent safety and environmental regulations, emphasizing our commitment to sustainability and corporate responsibility.

hpmc-hydroxypropyl methyl cellulose factory

Quality Control and Assurance

Quality control is paramount in our HPMC factory. Each batch of HPMC undergoes rigorous testing to ensure it meets the required specifications. We perform a comprehensive analysis of physical and chemical properties, including viscosity, moisture content, and purity levels. Our quality assurance team ensures that only HPMC that meets our high standards is released to our clients.

By investing in cutting-edge laboratory equipment and employing skilled technicians, we maintain our reputation for delivering reliable and high-quality products. Our dedication to quality not only satisfies regulatory requirements but also helps our customers achieve optimal results in their applications.

Diverse Applications

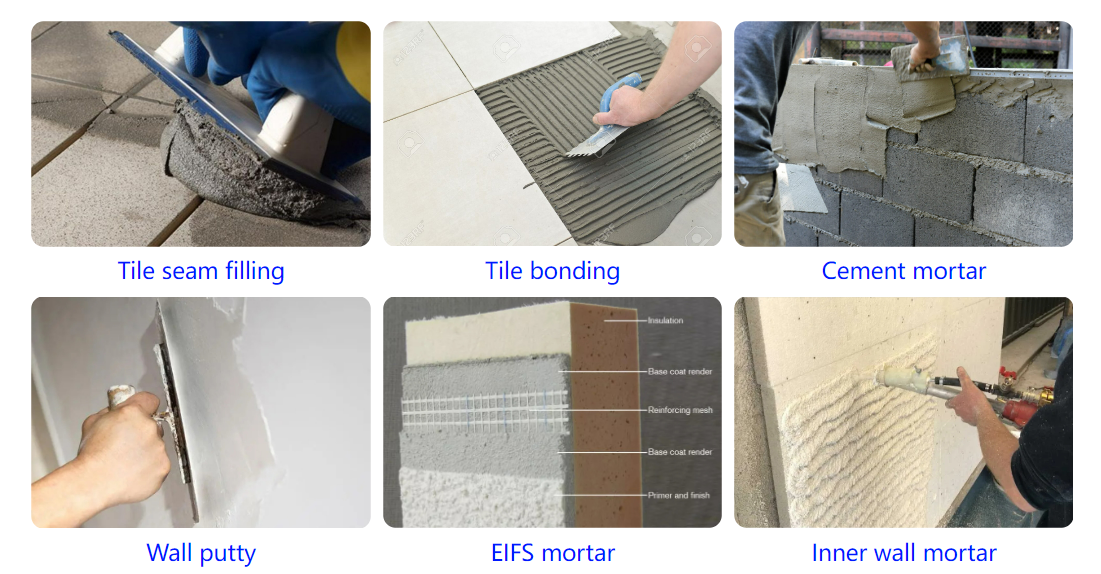

The versatility of HPMC allows it to be used in various sectors. In the pharmaceutical industry, HPMC acts as a binding agent in tablets, providing controlled release of active ingredients. In the food industry, it serves as a thickener and stabilizer, improving the texture and shelf life of products. Construction companies use HPMC as an additive in cement and mortar to enhance workability and adhesion. Moreover, in personal care and cosmetic products, it provides a smooth texture and aids in the uniform application of lotions and creams.

Conclusion

Our HPMC factory stands at the forefront of innovation and quality in the cellulose ether manufacturing industry. By leveraging modern technology, adhering to rigorous quality control standards, and focusing on sustainable practices, we produce high-quality HPMC that satisfies diverse requirements across numerous applications. As demand for HPMC continues to grow, our commitment to excellence ensures that we remain a trusted partner for our clients worldwide, contributing to their success in their respective fields.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025