Lap . 06, 2024 11:13 Back to list

Exploring the Properties and Applications of RDP Powder in Modern Industries

The Emergence of RDP Powder Revolutionizing Industries

In recent years, RDP powder, or Redispersible Polymer Powder, has captured significant attention across various industries due to its versatile applications and remarkable properties. This article delves into the characteristics, benefits, and applications of RDP powder, underscoring its growing importance in sectors such as construction, adhesives, and coatings.

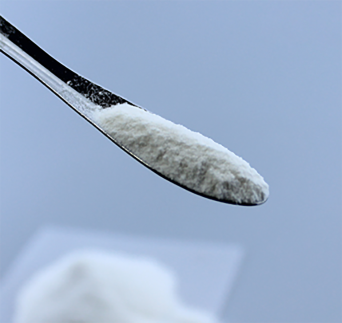

What is RDP Powder?

RDP powder is a type of polymer that is derived by spray-drying a dispersion of polymer particles. When added to a dry mortar mix, RDP powder rehydrates and forms a polymer film upon drying, enhancing the performance of construction materials. Primarily based on ethylene-vinyl acetate (EVA) or styrene-acrylic copolymers, RDP powder exhibits excellent adhesion, flexibility, and water resistance, making it an invaluable additive in various formulations.

Key Properties and Benefits

One of the standout features of RDP powder is its ability to improve the mechanical properties of mortars and renders. The addition of RDP enhances

1. Adhesion RDP powder significantly boosts the adhesion of mortars to various substrates, including concrete, masonry, and plaster. This results in improved durability and reduced risk of delamination.

2. Flexibility and Elasticity Mortars containing RDP maintain flexibility even after curing, allowing them to accommodate movements caused by temperature fluctuations or structural stress without cracking.

3. Water Resistance The water-repellent characteristics imparted by RDP powders extend the longevity of materials exposed to moisture, making them ideal for exterior applications.

4. Workability RDP enhances the workability of mortars, providing smoother mixing, easier application, and extended open time, which is crucial for large-scale projects.

5. Increased Durability The overall performance of construction products is markedly improved with RDP, resulting in enhanced resistance to weathering, abrasion, and chemicals—a vital factor for various construction applications.

Applications of RDP Powder

rdp powder

The versatility of RDP powder leads to its application in a wide range of products

- Dry Mortar Mixes RDP is extensively used in pre-mixed dry mortars, providing it with superior adhesion, flexibility, and durability. Typical applications include tile adhesives, jointing compounds, and repair mortars.

- External Insulation and Finishing Systems (EIFS) RDP powder is crucial in ensuring the adhesion and performance of insulation boards and finish coats, which require long-lasting durability against environmental conditions.

- Self-Leveling Compounds The use of RDP in self-leveling compounds results in improved flow and leveling properties, facilitating effortless installation and better surface finishes.

- Overlay Systems In decorative concrete applications, RDP powder helps achieve better adhesion and improves the aesthetic appeal and longevity of overlays.

- Adhesives and Sealants Beyond construction, RDP is used in the formulation of high-performance adhesives and sealants, where its exceptional bonding properties are vital.

Environmental Considerations

As the construction industry shifts towards sustainability, RDP powder stands out for its eco-friendliness. The use of RDP allows for lower cement content in formulations without compromising performance, contributing to reduced carbon emissions associated with cement production.

Moreover, many RDP products are formulated to be low in volatile organic compounds (VOCs), ensuring that they meet the stringent environmental standards increasingly demanded in construction practices.

Conclusion

RDP powder is a game changer in various industries, contributing to the sustainability and performance of construction materials. With its myriad benefits—enhanced adhesion, flexibility, durability, and workability—it is no wonder that RDP continues to gain traction and popularity. As the industry evolves and seeks innovative solutions to meet modern challenges, RDP powder will undoubtedly play an essential role in shaping the future of construction, adhesives, and coatings, ensuring both functionality and sustainability. As we look ahead, embracing materials like RDP is critical to progress in environmentally conscious and high-performance construction practices.

-

The Widespread Application of Redispersible Powder in Construction and Building Materials

NewsMay.16,2025

-

The Widespread Application of Hpmc in the Detergent Industry

NewsMay.16,2025

-

The Main Applications of Hydroxyethyl Cellulose in Paints and Coatings

NewsMay.16,2025

-

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

NewsMay.16,2025

-

HPMC: Application as a thickener and excipient

NewsMay.16,2025

-

Hec Cellulose Cellulose: Multi functional dispersants and high-efficiency thickeners

NewsMay.16,2025