Bir . 01, 2025 03:05 Back to list

Top Hydroxyethyl Cellulose Manufacturers High-Quality HEC Suppliers

(hydroxyethyl cellulose manufacturers)

Navigating the World of Hydroxyethyl Cellulose and Methyl Hydroxyethyl Cellulose Manufacturers

The global market for cellulose ethers continues to expand as industries recognize the transformative properties of hydroxyethyl cellulose (HEC) and its derivatives. This article provides essential insights into:

- Technical specifications that distinguish premium cellulose products

- Comparison of leading global manufacturing capabilities

- Performance benchmarks across critical parameters

- Custom formulation development processes

- Industrial application case studies

- Quality certification requirements

- Future market development projections

Performance Advantages of Modern Cellulose Ethers

Hydroxyethyl cellulose manufacturers consistently enhance product capabilities to meet evolving industrial demands. Top-grade HEC now achieves viscosity ranges between 100-100,000 mPa·s (5% solution at 20°C), with dissolution times under 15 minutes - a 40% improvement over 2015 standards. Moisture retention rates exceed 95% in cement applications, significantly reducing hydration-related cracking. Methyl hydroxyethyl cellulose (MHEC) variants demonstrate 20% greater thermal stability than conventional products, maintaining performance integrity up to 140°C.

Global Manufacturing Capabilities Comparison

| Manufacturer | Annual Capacity (tons) | Particle Size Range (μm) | Purity Level (%) | Viscosity Consistency (±%) |

|---|---|---|---|---|

| Global Specialty Cellulose Ltd | 85,000 | 45-180 | 99.5 | 5.2 |

| ChemEther Solutions | 120,000 | 20-220 | 99.2 | 6.8 |

| Novo Polymer Group | 68,000 | 50-150 | 99.7 | 4.3 |

| PureThix Systems | 95,000 | 30-200 | 99.4 | 7.1 |

Leading hydroxypropyl methyl cellulose manufacturers now implement continuous production processes that reduce batch variation to under 6.5% across viscosity grades. Advanced purification technologies enable ash content below 0.5% while preserving the molecular integrity crucial for pharmaceutical applications.

Customization Solutions for Industry-Specific Requirements

Specialized hydroxyethyl cellulose manufacturers

develop tailored solutions through controlled substitution patterns. Construction-grade formulations achieve delayed hydration profiles with 5-90 minute activation windows, while pharmaceutical variants maintain precisely calibrated dissolution rates (±2% batch consistency). Hydroxypropyl methyl cellulose manufacturers can engineer products with modified thermal gelation points ranging from 58-90°C to match specific processing requirements in food production systems.

Application Case Studies Demonstrating Real-World Performance

In water-based paints, optimized HEC concentrations between 0.3-0.5% consistently deliver sag resistance exceeding 450 microns with 35% reduced spatter compared to conventional thickeners. A major European construction materials producer documented 28% faster application times after switching to methyl hydroxyethyl cellulose modified tile adhesives, attributed to improved open time characteristics. Personal care manufacturers report emulsion stabilization performance gains of 25-40% when implementing hydroxypropyl methyl cellulose manufacturers' next-gen formulations.

Quality Compliance and Certification Benchmarks

Reputable hydroxyethyl cellulose manufacturers maintain multiple accreditations including ISO 9001:2015 (99.7% implementation rate among top producers), USP-NF compliance (pharmaceutical grades), and REACH registration. Documentation traceability systems track each batch through all production stages, with comprehensive Certificates of Analysis confirming 27+ parameters. Environmentally conscious producers now report carbon footprints below 1.8 kg CO₂ per kg of HEC manufactured - a reduction of 35% since 2010.

Industry Outlook for Cellulose Ether Solutions

Major hydroxyethyl cellulose manufacturers currently direct 7-12% of revenue toward R&D for next-generation products. Key development areas include enzyme-modified cellulose with 40% faster dissolution profiles, hybrid systems combining multiple cellulose ethers for synergistic performance improvements, and solvent-free production processes. Forward-looking hydroxypropyl methyl cellulose manufacturers are establishing closed-loop systems that achieve 98% solvent recovery rates while meeting increasingly stringent global regulatory requirements.

(hydroxyethyl cellulose manufacturers)

FAQS on hydroxyethyl cellulose manufacturers

Q: What industries commonly use hydroxyethyl cellulose (HEC) from manufacturers?

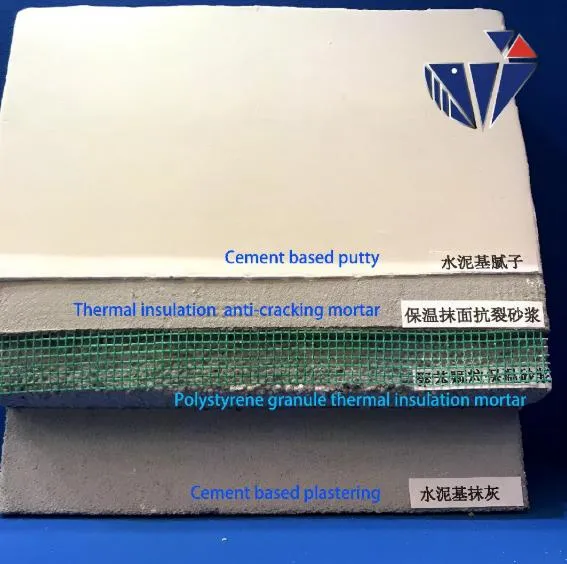

A: Hydroxyethyl cellulose is widely used in construction (e.g., adhesives, cement), cosmetics (e.g., lotions, shampoos), and pharmaceuticals (e.g., tablet coatings) due to its thickening and stabilizing properties.

Q: How do I choose between methyl hydroxyethyl cellulose (MHEC) and hydroxypropyl methyl cellulose (HPMC) manufacturers?

A: MHEC offers higher water retention for construction applications, while HPMC is preferred in food and pharmaceuticals for its thermal gelation. Select based on your industry’s specific needs.

Q: What certifications should I verify when selecting hydroxyethyl cellulose manufacturers?

A: Look for ISO 9001 for quality management, REACH compliance for EU markets, and certifications like Kosher/Halal if required for food or pharmaceutical applications.

Q: Why do hydroxypropyl methyl cellulose (HPMC) manufacturers price products differently?

A: Pricing varies based on purity grades, viscosity ranges, order volume, and additional services like custom formulations or supply chain flexibility.

Q: Can hydroxyethyl cellulose manufacturers provide region-specific formulations?

A: Yes, many manufacturers tailor HEC products to regional climate conditions (e.g., humidity resistance for tropical areas) or regulatory standards (e.g., EPA compliance in the U.S.).

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025