ធ្នូ . 20, 2024 12:48 Back to list

redispersible polymer powder wikipedia

Understanding Redispersible Polymer Powder Composition, Applications, and Benefits

Redispersible polymer powders (RDPs) are specialized additives that play a crucial role in various industries, mainly in construction, coatings, and adhesives. These powders are commonly used to enhance the performance of cement-based and other water-based formulations. As a versatile ingredient, RDPs are designed to improve product properties such as flexibility, adhesion, water resistance, and overall durability.

Composition of Redispersible Polymer Powder

RDPs are typically produced by spray-drying aqueous polymer dispersions. The primary types of polymers used in their formulation include vinyl acetate-ethylene (VAE) copolymers, styrene-acrylic copolymers, and other variations tailored for specific application needs. The spray-drying process involves removing water from the polymer dispersion while preserving the polymer's properties. This results in a fine powder that can rehydrate and redisperse in water.

One of the key advantages of RDPs is their ability to create a film-forming agent upon redispersion in water. When mixed with a liquid medium, RDPs rehydrate and form a uniform, continuous film that can trap air, thus contributing to improved elasticity and flexibility in the final product. This property is vital in applications where movement or structural changes are expected.

Applications of Redispersible Polymer Powder

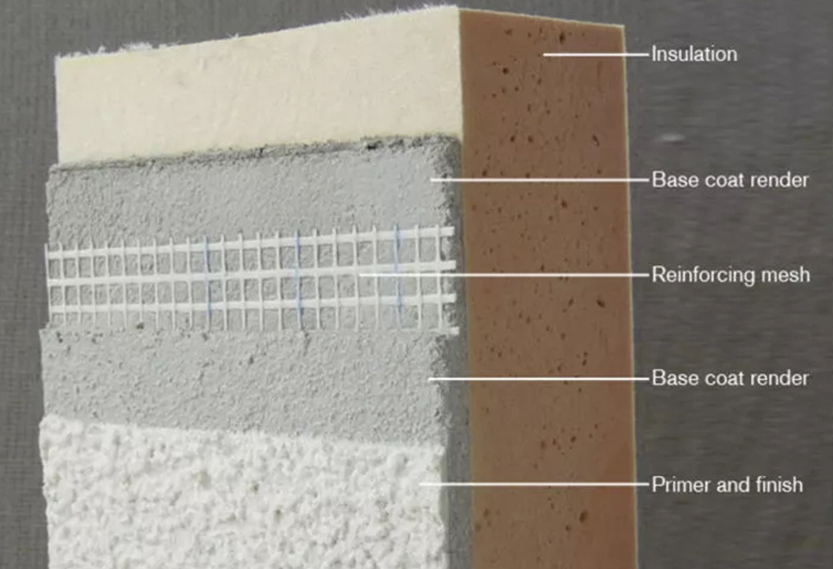

RDPs are predominantly utilized in construction materials, particularly in the formulation of tile adhesives, dry-mix mortars, plasters, and other masonry products. Their inclusion enhances the bonding strength and reduces water permeability, making them particularly suited for applications in wet and humid environments. Furthermore, RDPs also provide improved workability, allowing for easier application and manipulation during construction activities.

Beyond construction, RDPs find applications in coatings, where they enhance adhesion and durability. In paints and coatings, RDPs contribute to a smoother application process and improved resistance to weathering, UV light, and other environmental factors. This makes them invaluable in both interior and exterior applications.

In the adhesive industry, RDPs improve the performance characteristics of various adhesive formulations, making them ideal for a wide range of substrates, including porous and non-porous materials. Their ability to enhance flexibility and reduce brittleness makes them particularly useful for adhesives that are exposed to dynamic stresses.

redispersible polymer powder wikipedia

Benefits of Using Redispersible Polymer Powder

The integration of RDPs into various formulations offers numerous benefits. One of the primary advantages is improved adhesion and cohesion, which enhances the overall strength of the final product. This is especially important in construction applications, where structural integrity is paramount.

Another significant benefit is the enhancement of flexibility and elasticity, which allows finished products to withstand thermal and mechanical stress without cracking or damaging. This characteristic is essential for applications such as tile adhesives, where movement between bonded surfaces can occur.

RDPs also contribute to better moisture resistance in formulations, an essential feature in environments where water exposure is frequent. This results in longer-lasting products that can endure extreme conditions without degrading.

Moreover, the use of RDPs can improve the working properties of formulation mixtures, allowing for easier application and reduced labor costs in construction and manufacturing processes. The improved consistency and stability of the mixtures make them more user-friendly.

Environmental Considerations

With the growing emphasis on sustainability, the environmental impact of construction materials is a significant concern. RDPs contribute positively by enabling the use of lower quantities of cement and other binders, thus reducing carbon emissions associated with material production. Additionally, by enhancing the performance of formulations, RDPs can increase the lifespan of products, further contributing to sustainable building practices.

Conclusion

Redispersible polymer powders are multifunctional additives with a wide range of applications, particularly in construction, coatings, and adhesives. Their unique properties significantly enhance the performance, durability, and application characteristics of various formulations. As industries continue to seek more efficient, sustainable, and high-performing materials, RDPs are poised to play an even more vital role in the future of product development and construction. Understanding their composition and benefits can help professionals make informed decisions when selecting materials for their specific needs.

-

The Widespread Application of Redispersible Powder in Construction and Building Materials

NewsMay.16,2025

-

The Widespread Application of Hpmc in the Detergent Industry

NewsMay.16,2025

-

The Main Applications of Hydroxyethyl Cellulose in Paints and Coatings

NewsMay.16,2025

-

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

NewsMay.16,2025

-

HPMC: Application as a thickener and excipient

NewsMay.16,2025

-

Hec Cellulose Cellulose: Multi functional dispersants and high-efficiency thickeners

NewsMay.16,2025