ធ្នូ . 11, 2024 10:20 Back to list

Exploring the Impact of HPMC on Viscosity and Its Practical Applications

Understanding HPMC Viscosity Applications and Importance

Hydroxypropyl Methylcellulose (HPMC) is a versatile polymer widely used in various industries, particularly in pharmaceuticals, food, and construction. Its unique properties, including water solubility and thickening ability, are largely attributed to its viscosity. Viscosity, in simple terms, is a measure of a fluid's resistance to flow. In the context of HPMC, understanding viscosity is crucial for determining its functionality and application across different fields.

Understanding HPMC Viscosity Applications and Importance

In the pharmaceutical industry, HPMC is primarily used as a binder, film-forming agent, and thickening agent in formulations. Its viscosity plays a pivotal role in controlling the texture and release characteristics of oral medications, creams, and gels. High viscosity grades are often utilized in products that require a thicker consistency, which can enhance stability and performance. For instance, in controlled-release formulations, HPMC can slow down the release of active ingredients, improving therapeutic effectiveness and patient compliance.

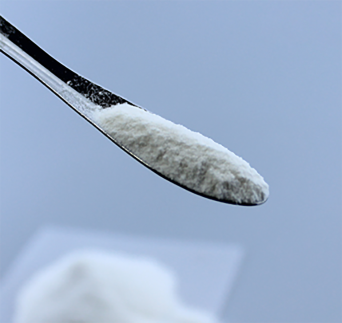

hpmc viscosity

In the food industry, HPMC serves as an emulsifier, stabilizer, and thickener. Its ability to retain moisture makes it an essential ingredient in various food products, particularly in gluten-free formulations where it helps to improve texture and mouthfeel. The viscosity of HPMC is critical in determining how it interacts with other ingredients, influencing the overall quality and acceptability of food products. For example, HPMC can create a desirable creamy texture in sauces and dressings while also extending shelf life.

The construction sector also benefits from HPMC's viscosity properties, particularly in tile adhesives, mortars, and other building materials. Here, HPMC acts as a water-retention agent, which is vital for ensuring that the materials remain workable for longer periods. The viscosity of HPMC affects the adhesion properties of these materials, influencing their application and performance. A well-optimized viscosity ensures that the adhesives maintain their workability while providing strong bond strengths upon curing.

To measure the viscosity of HPMC, several techniques are employed, including the use of Brookfield viscometers and rotational viscometers. Understanding and controlling the viscosity is crucial for manufacturers as it directly impacts product performance and consumer satisfaction. In practice, formulators often experiment with various HPMC grades to achieve the desired viscosity and performance characteristics necessary for specific applications.

In conclusion, the viscosity of Hydroxypropyl Methylcellulose is a fundamental aspect that influences its functionality across multiple industries. From pharmaceuticals to food and construction, understanding and manipulating HPMC viscosity can lead to improved products and enhanced performance. As industries continue to evolve and seek innovative solutions, HPMC's role and its viscosity will remain integral to the development of effective, high-quality products that meet consumer needs. Whether in a pill, a delicious sauce, or a sturdy adhesive, the importance of HPMC viscosity cannot be overstated.

-

Why HPMC is a Key Additive in Wall Putty Formulations

NewsAug.05,2025

-

Redispersible Powder in Decorative Renders: Function Meets Finish

NewsAug.05,2025

-

Redispersible Powder for Interior Wall Putty: Smooth Results Every Time

NewsAug.05,2025

-

HPMC’s Water Retention Capacity in Dry Mortar Applications

NewsAug.05,2025

-

HPMC Factory Contributions to Liquid Detergents

NewsAug.05,2025

-

How HPMC Factory Products Change Detergent Textures

NewsAug.05,2025