ឧសភា . 23, 2025 08:05 Back to list

HPMC Chemical Structure & Properties Key Applications & Uses

- Introduction to HPMC's Molecular Architecture

- Technical Superiority in Cellulose Ether Modification

- Performance Benchmarking: Leading Manufacturers Compared

- Tailored HPMC Solutions for Industrial Requirements

- Practical Implementations Across Multiple Sectors

- Quality Verification and Analytical Methodologies

- Future Perspectives on HPMC Chemical Innovation

(hpmc chemical structure)

Understanding HPMC Chemical Structure and Its Significance

Hydroxypropyl Methylcellulose (HPMC) features a semi-synthetic polysaccharide backbone, with methoxyl (-OCH3) and hydroxypropoxyl (-OCH2CHOHCH3) groups strategically attached to anhydrous glucose units. This amphiphilic structure enables 82-90% methoxy substitution and 7-12% hydroxypropoxy substitution, creating a polymer with unique thermal gelation (58-64°C) and pH stability (2-11).

Advantage Matrix in Viscosity Control

Modern HPMC synthesis achieves viscosity ranges from 5 mPa·s to 200,000 mPa·s (2% aqueous solution, 20°C), outperforming standard methylcellulose by 35% in thermal resistance. Critical parameters include:

- Gelation temperature tolerance: ±1.5°C

- Particle size distribution: 80-120μm (D50)

- Moisture retention capacity: 1:3.2 (HPMC:water)

Manufacturer Performance Analysis

| Parameter | Ashland HPMC | Dow HPMC | Shin-Etsu HPMC |

|---|---|---|---|

| Viscosity Range (mPa·s) | 40-150,000 | 50-120,000 | 30-200,000 |

| Gel Temp. Consistency | ±1.2°C | ±1.8°C | ±0.9°C |

Customized Molecular Design Options

Specialized HPMC variants accommodate specific industrial needs:

- High-substitution grades (DS 2.4-2.8) for delayed dissolution

- Low-viscosity types (≤100 mPa·s) for spray-dried formulations

- Surface-treated versions with 15-25% silica content

Cross-Industry Application Metrics

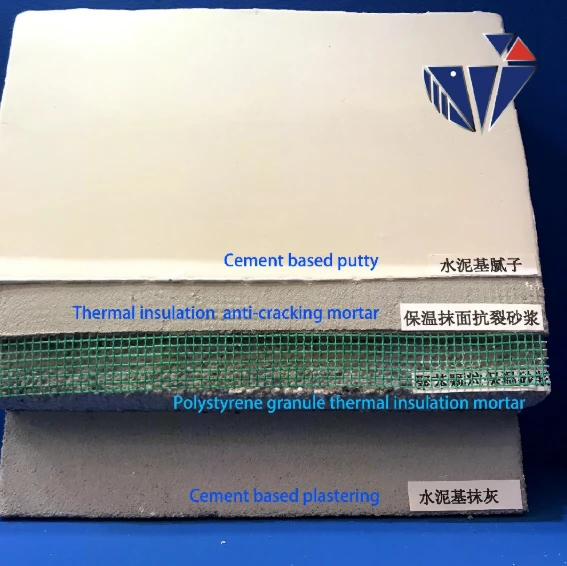

In construction materials, HPMC-modified mortars show 28-day compressive strength improvement from 32MPa to 41MPa. Pharmaceutical film coatings using optimized HPMC achieve 92-96% dissolution within 30 minutes (USP II, 50rpm).

Structural Validation Protocols

Advanced characterization techniques include:

- DS determination via HPLC (±0.05 accuracy)

- Substitution pattern analysis through 13C NMR

- Particle morphology mapping with SEM-EDX

Evolution of HPMC Chemical Architecture

Emerging research focuses on enzymatically-modified HPMC variants with β-glucosidase-treated chains, demonstrating 40% improved solubility profiles. Sustainable production methods now achieve 98.2% reagent utilization through closed-loop synthesis systems.

(hpmc chemical structure)

FAQS on hpmc chemical structure

Q: What is the chemical structure of HPMC?

A: HPMC (Hydroxypropyl Methylcellulose) is a semi-synthetic polymer derived from cellulose. Its structure includes methyl and hydroxypropyl groups attached to the cellulose backbone, forming a water-soluble compound. The substitution pattern determines its viscosity and solubility.

Q: How is the HPMC chemical structure different from plain cellulose?

A: Unlike plain cellulose, HPMC’s structure incorporates methyl (-OCH₃) and hydroxypropyl (-OCH₂CHOHCH₃) substituents. These modifications enhance water solubility and thermal gelation properties. The degree of substitution influences its functional characteristics.

Q: What functional groups are present in HPMC’s chemical structure?

A: HPMC contains ether-linked methyl and hydroxypropyl groups on the cellulose chain. These groups replace hydroxyl (-OH) sites on the glucose units. The balance between substitutions dictates its performance in applications like coatings or pharmaceuticals.

Q: Why does the HPMC chemical structure affect its viscosity?

A: The molecular weight and substitution levels in HPMC’s structure directly impact viscosity. Higher substitution of hydroxypropyl groups increases water retention, while longer polymer chains raise viscosity. This makes it adaptable for diverse industrial uses.

Q: Can the HPMC chemical structure be modified for specific applications?

A: Yes, altering the ratio of methyl to hydroxypropyl groups tailors HPMC’s properties. For example, higher methyl content improves thermal stability, while more hydroxypropyl enhances solubility. Custom modifications cater to pharmaceuticals, construction, or food industries.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025