វិច្ឆិកា . 08, 2024 11:11 Back to list

Understanding the Benefits and Applications of Dispersible Polymer Powders in Various Industries

Understanding Dispersible Polymer Powder and Its Applications

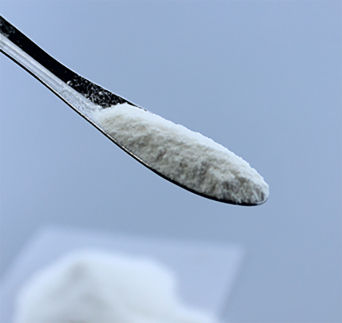

Dispersible polymer powders have gained significant attention in various industries due to their unique properties and the versatility they offer. These fine powders are composed of polymers that can be easily dispersed in water or other solvents, leading to the formation of stable colloidal dispersions. These materials play a crucial role in enhancing the performance of a wide range of products, making them indispensable in modern manufacturing processes.

The Composition and Characteristics of Dispersible Polymer Powders

Dispersible polymer powders are typically made from synthetic and natural polymers. Common examples include polyvinyl acetate (PVAc), polyacrylate, and styrene-acrylic copolymers. The main characteristic of these powders is their ability to form stable dispersions upon being mixed with water, which can then be utilized in various applications. The particle size, molecular weight, and degree of cross-linking are key factors that affect the performance of these powders.

One of the standout features of dispersible polymer powders is their ease of handling. Unlike conventional liquid polymers, which may require complex mixing and storage conditions, these powders can be easily transported and stored in a dry form. This not only reduces shipping costs but also extends the shelf life of the product.

Applications in Various Industries

1. Construction Industry Dispersible polymer powders are extensively used in the construction sector, particularly in the formulation of adhesives, sealants, and coatings. They significantly enhance the flexibility, adhesion, and water resistance of these products. For instance, when added to cement-based formulations, these powders improve the workability of the mixture, allowing for easier application and better finishing results.

dispersible polymer powder

2. Paints and Coatings In the paint and coating industry, dispersible polymer powders contribute to improved durability, weather resistance, and color retention. They enhance the film-forming properties of paints, providing a smooth finish and optimal coverage. Additionally, these powders help in reducing the VOC (volatile organic compound) emissions, making them a more environmentally friendly option.

3. Textiles The textile industry benefits from dispersible polymer powders by incorporating them into fabric coatings and finishes. These powders enhance the water repellency, stain resistance, and overall durability of textiles. Furthermore, they contribute to the production of non-woven fabrics, which are used in various applications, including medical and hygiene products.

4. Adhesives and Sealants Dispersible polymer powders play a crucial role in formulating adhesives and sealants, offering superior bonding strength and flexibility. They improve the performance of both water-based and solvent-based adhesives, making them suitable for a wide range of substrates, including wood, metal, and plastics.

Future Trends and Innovations

As industries continue to seek sustainable and high-performance materials, the demand for dispersible polymer powders is expected to grow. Innovations in polymer chemistry and processing techniques are paving the way for the development of new types of dispersible powders with tailored properties. Additionally, the rising focus on eco-friendly materials and practices is encouraging manufacturers to explore biodegradable options and reduce the environmental impact of traditional polymer powders.

In conclusion, dispersible polymer powders are versatile materials that have found applications across multiple industries. Their unique properties, ease of use, and benefits in enhancing product performance make them an essential component in modern manufacturing. As technology advances and the demand for sustainable solutions increases, we can expect these polymer powders to play an even more significant role in the future of various industries.

-

The Widespread Application of Redispersible Powder in Construction and Building Materials

NewsMay.16,2025

-

The Widespread Application of Hpmc in the Detergent Industry

NewsMay.16,2025

-

The Main Applications of Hydroxyethyl Cellulose in Paints and Coatings

NewsMay.16,2025

-

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

NewsMay.16,2025

-

HPMC: Application as a thickener and excipient

NewsMay.16,2025

-

Hec Cellulose Cellulose: Multi functional dispersants and high-efficiency thickeners

NewsMay.16,2025