თებ . 06, 2025 04:11 Back to list

hpmc for tile adhesive

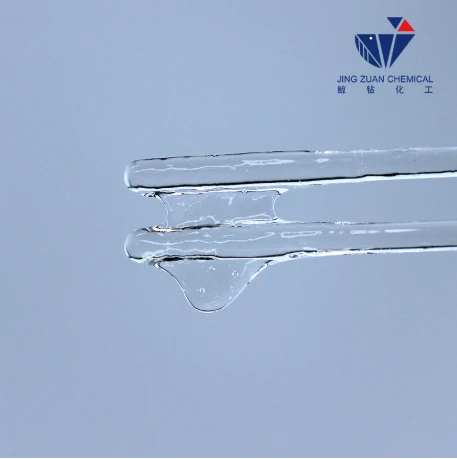

Trustworthiness in HPMC dispersion is reinforced by adherence to high manufacturing standards and quality controls. Manufacturers regularly conduct inspections and quality assessment tests to ensure that each batch of HPMC meets specific criteria. Additionally, third-party certifications often accompany these products, further validating their safety and efficacy. Professionals in product development rely heavily on these certifications as a testament to the ingredient's reliability. In practical applications, such as in the construction industry, HPMC’s dispersion plays a pivotal role in the performance of tile adhesives. A well-dispersed HPMC ensures that these adhesives possess the right amount of workability and open time, essential for effective application and bonding. Similarly, in pharmaceuticals, the dispersion qualities of HPMC are critical in controlled-release tablets, where a uniform distribution influences the release rate of the active ingredients, thereby impacting the drug's efficacy and patient outcomes. In summary, HPMC dispersion embodies a unique blend of hands-on experience, specialized knowledge, authoritative guidance, and credible quality assurance. Each of these elements not only highlights the expertise required to use HPMC effectively but also establishes a comprehensive framework for its responsible application across various industries. With its proven track record and ongoing innovations, HPMC continues to be a cornerstone material that meets the dynamic demands of modern product development.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025