თებ . 01, 2025 01:10 Back to list

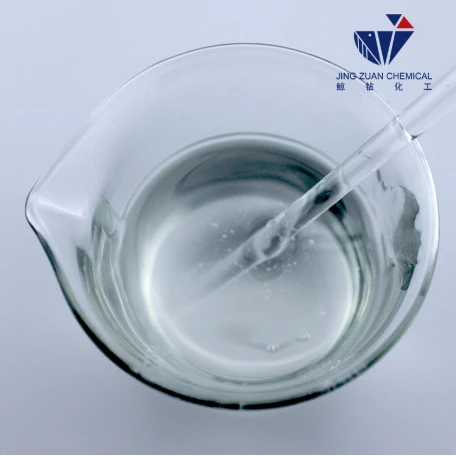

how to dissolve hydroxyethyl cellulose

Monitoring viscosity changes is a reliable method to gauge the dissolution progress. Turbidity can also indicate incomplete dissolution, especially if visible particle contamination remains. Therefore, consistent quality checks, by taking small samples for microscanning, can help detect any undissolved particles, ensuring a homogeneous mixture before the product moves to the next stage of processing or packaging. Another essential factor is the pH of the solution. HEC is generally stable over a wide pH range but achieving optimal viscosity may require pH adjustments, primarily in formulations where pH-sensitive components are present. Ensure the pH range remains compatible with all formulation components to avoid destabilizing the HEC structure. For storage, solutions of HEC should be placed in clean, contamination-free containers, protected from microbial growth which can compromise the formulation. Utilizing preservatives compatible with HEC and the desired application can extend the shelf life of these solutions, maintaining their consistency and efficacy. In summary, dissolving hydroxyethyl cellulose effectively involves choosing the appropriate grade, controlling dissolution conditions, preventing lump formation, monitoring physical changes, and ensuring stability. Mastery of these factors not only enhances the desired properties of the product but also aligns with the principles of trust and reliability, fostering credibility in the quality of your formulations.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025