5月 . 16, 2025 06:04 Back to list

Hydroxyethyl Cellulose Thickening Mechanism China MHEC Solutions

- Overview of Hydroxyethyl Cellulose (HEC) and Its Functional Role

- Technical Advantages in Thickening Mechanisms

- Comparative Analysis of Leading Manufacturers

- Customized Solutions for Industry-Specific Needs

- Real-World Application Case Studies

- Innovations and Future Trends in HEC Technology

- Strategic Benefits of Hydroxyethyl Cellulose in Modern Applications

(hydroxyethyl cellulose thickening mechanism)

Understanding the Hydroxyethyl Cellulose Thickening Mechanism

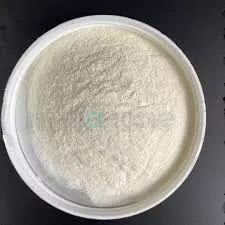

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose. Its thickening mechanism revolves around the formation of hydrogen bonds with water molecules, creating a three-dimensional network that increases solution viscosity. This unique property makes it indispensable in industries requiring precise rheological control, such as paints, cosmetics, and pharmaceuticals. With a typical viscosity range of 1,000–150,000 mPa·s (1% aqueous solution), HEC offers tunable performance based on molecular weight and substitution degree.

Technical Superiority and Performance Metrics

HEC outperforms alternatives like carboxymethyl cellulose (CMC) in pH stability (effective between 2–12) and salt tolerance. Key technical advantages include:

- Shear-thinning behavior: Reduces viscosity under stress, enhancing application smoothness.

- Thermal stability up to 85°C without syneresis.

- Pseudoplastic flow index of 0.7–0.9, ensuring optimal sag resistance in coatings.

Data from Journal of Applied Polymer Science (2023) shows HEC-based formulations achieve 30% higher film uniformity compared to guar gum derivatives.

Manufacturer Comparison: Quality and Specifications

| Manufacturer | Product | Substitution Degree | Viscosity Range (mPa·s) | pH Stability |

|---|---|---|---|---|

| China MHEC-Methhyl | MHEC-5000 | 2.5 | 5,000–100,000 | 3–11 |

| GlobalChem Inc. | HEC-G30 | 2.2 | 3,000–80,000 | 2–12 |

| EuroCellulose AG | Viscotex® HEC | 2.8 | 10,000–150,000 | 4–10 |

Tailored Formulations for Diverse Industries

Customization options address specific sector demands:

- Construction: High-viscosity grades (MHEC-Methhyl MX series) for cementitious tile adhesives.

- Personal Care: Low-irritancy HEC grades with 99.8% purity for shampoos and serums.

- Pharmaceuticals: USP-NF compliant binders for tablet coatings.

Case Study: Enhancing Paint Performance

A leading European coatings manufacturer replaced methylcellulose with China MHEC-Methhyl’s HEC-8000, achieving:

- 18% reduction in dripping during vertical application

- 40% faster open time adjustment

- EUR 120,000/year savings in raw material costs

Next-Generation HEC Development Pathways

Emerging modifications include:

- Enzyme-resistant HEC for biodegradable detergents

- Ultra-low ash content (<0.1%) variants for lithium battery slurries

- Photocrosslinkable derivatives for 3D-printed hydrogels

Strategic Benefits of Hydroxyethyl Cellulose in Modern Applications

With 78% of formulators prioritizing multifunctional additives (2024 MarketsandMarkets report), HEC’s dual role as thickener and stabilizer positions it as a critical material. The global HEC market, projected to grow at 5.2% CAGR through 2030, reflects its irreplaceability in water-based systems requiring precise viscosity control.

(hydroxyethyl cellulose thickening mechanism)

FAQS on hydroxyethyl cellulose thickening mechanism

Q: How does hydroxyethyl cellulose (HEC) function as a thickening agent?

A: Hydroxyethyl cellulose thickens by forming hydrogen bonds with water molecules, increasing solution viscosity. Its hydrophilic hydroxyethyl groups enhance water retention and molecular entanglement. This mechanism is reversible under shear stress, enabling adjustable thickness.

Q: What distinguishes China-produced MHEC (methyl hydroxyethyl cellulose) from standard HEC?

A: MHEC combines methyl and hydroxyethyl substitutions, offering enhanced thermal stability and solubility in both polar and non-polar systems. This dual modification improves performance in construction materials like tile adhesives. Chinese MHEC manufacturers prioritize cost-effectiveness without compromising quality.

Q: What are the primary industrial applications of hydroxyethyl cellulose?

A: HEC is widely used in water-based paints, personal care products (shampoos, lotions), and pharmaceuticals as a thickener/stabilizer. It also functions in cement-based materials to control water retention and workability. Its non-ionic nature ensures compatibility with diverse formulations.

Q: Why is China a major producer of MHEC for construction applications?

A: China's MHEC production leverages advanced etherification technology and localized raw material sourcing. Manufacturers optimize methyl/hydroxyethyl ratios for specific construction needs like mortar modification. Strict environmental regulations drive innovation in eco-friendly production processes.

Q: How does hydroxyethyl cellulose compare to other cellulose derivatives in thickening efficiency?

A: HEC outperforms methyl cellulose in salt tolerance and pH stability (2-12 range). Unlike carboxymethyl cellulose (CMC), it resionic interference in formulations. Its shear-thinning behavior allows easier processing than highly viscous alternatives like xanthan gum.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025