nóv . 01, 2024 03:35 Back to list

HPMC Hydroxypropyl Methyl Cellulose Production and Supply Information

HPMC, or Hydroxypropyl Methyl Cellulose, is a versatile and widely used polymer derived from cellulose. It has found its applications in various industries, including pharmaceuticals, food, construction, and personal care products. The manufacturing process of HPMC requires meticulous attention to detail and quality control to ensure that the end product meets the specific needs of different applications.

The primary raw material used in the production of HPMC is cellulose, which is sourced from plant fibers. The cellulose is subjected to a series of chemical modifications to produce hydroxypropyl and methyl groups, which enhance its solubility and functionality. The process typically involves etherification, where cellulose is treated with an alkaline solution and propylene oxide, followed by a reaction with methyl chloride. This complex process results in a stable, thickening, and film-forming agent that has remarkable properties.

One of the key advantages of HPMC is its versatility. In the pharmaceutical industry, for instance, HPMC is utilized as a binder, coating agent, and controlled-release polymer in drug formulations. Its ability to form a gel in the presence of water makes it suitable for various dosage forms, including tablets, capsules, and suspensions. Additionally, HPMC is employed as an excipient in the formulation of ointments and creams, ensuring consistent texture and stability.

hpmc-hydroxypropyl methyl cellulose manufacturer

In the food industry, HPMC serves as a thickening and stabilizing agent in various food products, enhancing their texture and preventing undesired separation. Its use in gluten-free baking has gained popularity, as it helps mimic the elasticity and structure that gluten provides in traditional baked goods. This characteristic is particularly valuable for creating a more enjoyable eating experience for those with gluten sensitivities.

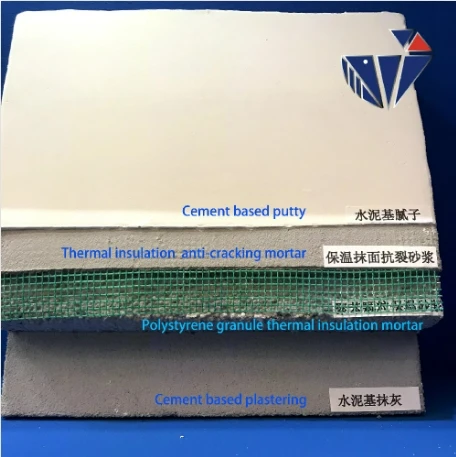

The construction industry also benefits from HPMC, where it is used as an additive in cement-based products, such as tile adhesives and plasters. Its water-retention properties improve workability and extend the open time of these materials, leading to enhanced performance and durability.

Overall, the role of HPMC as a hydroxypropyl methyl cellulose manufacturer is critical in ensuring that various industries have access to high-quality products that meet stringent safety and efficacy standards. Manufacturers invest in research and development to optimize the properties and performance of HPMC, catering to the evolving needs of their customers. As industries continue to innovate and demand more from their materials, HPMC is poised to remain a key player in delivering effective solutions across a wide range of applications.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025