Jan . 21, 2025 03:38 Back to list

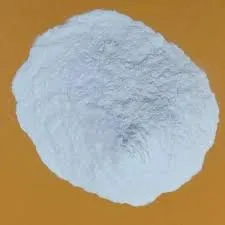

hpmc for tile adhesive

The relevance of HPMC density extends beyond just the scientific understanding; it involves a holistic approach that considers regulatory compliance, safety standards, and consumer expectations. Expertise in this domain often requires interfacing with research and development teams, engaging with academic research, and staying updated with regulatory frameworks to ensure that the use of HPMC meets international standards. For instance, variations in climate and environmental conditions may necessitate adjustments in the density of HPMC formulations to maintain efficacy and stability, especially in global distribution scenarios. Furthermore, the credibility of products using HPMC is often built on the reliability and consistency of their formulations. Through rigorous testing and validation processes, manufacturers can instill confidence in end-users. Authoritative voices in the industry, such as academic experts and seasoned chemists, often contribute invaluable insights that help refine the use of HPMC, ensuring its properties are leveraged to their highest potential. Trust also plays a crucial role, where transparent communication regarding the composition and application of HPMC can enhance consumer confidence. Companies that prioritize educating their consumers about the role and benefits of HPMC, including detailed information about how density affects their products, tend to foster a more trusting relationship with their customers. In conclusion, the density of hydroxypropyl methylcellulose is more than a mere physical characteristic—it is a critical factor that influences a product's functionality across multiple applications. Professionals who navigate the complexities of HPMC ensure that its potential is harnessed efficiently, integrating their experience and expertise to produce superior outcomes. As industries continue to evolve, the knowledge surrounding HPMC and its properties, particularly density, will undoubtedly remain a cornerstone of product innovation and quality assurance, driving success both in market performance and in the trust of consumers worldwide.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025