Sep . 01, 2024 09:08 Back to list

hpmc grades and uses

Understanding HPMC Grades and Their Uses

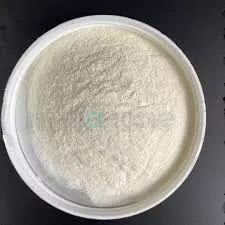

Hydroxypropyl Methylcellulose (HPMC) is a versatile polymer derived from cellulose, primarily used in various industries due to its unique properties. It is a non-ionic, water-soluble polymer that can form transparent films and gel-like structures. The varying grades of HPMC are determined by the degree of substitution of methoxy and hydroxypropyl groups, which influence its physical and chemical attributes. This article aims to explore the different grades of HPMC and their respective applications.

Grades of HPMC

HPMC is available in several grades, each tailored for specific applications. The most common grades are categorized based on viscosity, hydroxypropyl content, and methoxy content. The viscosity of HPMC ranges from low to high, usually measured in centipoise (cP), and indicates the thickness of the solution when HPMC is dissolved in water. Low viscosity grades, such as HPMC E3 (3,000 cP), are generally used for applications requiring lower thickness, while high viscosity grades, such as HPMC E15 (15,000 cP) and E50 (50,000 cP), are used in applications where higher viscosity is needed.

Applications in Pharmaceuticals

One of the most significant uses of HPMC is in the pharmaceutical industry. HPMC is used as a binder in tablet formulations, as it helps in controlling the release of active pharmaceutical ingredients (APIs). Additionally, HPMC can be employed as a film-coating agent, providing a protective layer to pills while ensuring the controlled release of drugs. Its non-toxic nature and compatibility with various substances make it a favored choice in drug delivery systems, including controlled-release formulations.

HPMC’s ability to form gels is utilized in producing matrix tablets, which provide prolonged action of medications. Furthermore, HPMC is beneficial in creating ophthalmic preparations due to its eye-friendly properties, ensuring comfort and ease of use in eye drops.

hpmc grades and uses

Food Industry Applications

In the food industry, HPMC is prized for its emulsifying, thickening, and stabilizing properties. It is commonly used in baking, sauces, dairy products, and desserts. HPMC enhances texture while retaining moisture, which is crucial in food preservation. Moreover, it is often used in gluten-free products, as it mimics the elasticity and texture provided by gluten, making the product more palatable.

Cosmetics and Personal Care

HPMC is also widely employed in cosmetics and personal care products. Its film-forming capabilities make it effective for use in hair gels, lotions, and creams, providing a smooth feel upon application. It acts as a thickener and stabilizer in formulations, ensuring consistency and enhancing the product's overall aesthetic appeal.

Conclusion

The diverse grades of Hydroxypropyl Methylcellulose (HPMC) contribute significantly to its multifunctional nature, making it a crucial ingredient in various sectors. From pharmaceuticals to food, and cosmetics to construction, HPMC's unique properties allow for a wide range of applications. Its ability to adapt to specific requirements based on viscosity and chemical composition solidifies its place as an essential compound in modern material science and industry. Understanding the different grades of HPMC and their uses enables professionals across industries to harness its potential effectively, driving innovation and improving product quality.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025