Jul . 01, 2024 14:51 Back to list

Hydroxypropyl Methylcellulose

Hydroxypropyl Methylcellulose

Also known as Hypromellose or HPMC

What is Hydroxypropyl Methylcellulose?

Hydroxypropyl Methylcellulose (HMPC) is a polysaccharide additive used in frosting, coatings, gluten-free baking and dietary supplements. It is also a stabilizer, thickener, fat replacer, bulking and binding agent. 1

Several types of HPMC are available commercially in several degrees of substitution, mainly:1, 2.

- HPMC – type C: high methyl and hydroxypropyl content.

- HPMC – type D: high methyl and medium hydroxypropyl content.

- HPMC – type E: medium methyl and hydroxypropyl content.

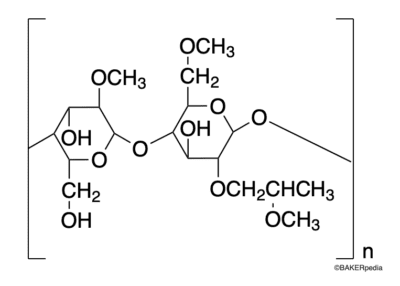

Chemical Structure

Origin

Hydroxypropyl Methylcellulose is obtained from various natural sources, mainly wood pulp and cotton linters. 1

Since 1985, HPMC has been used as a gluten replacement for the manufacture of baked goods.3

HPMC

Function

HPMC can serve several functions in baked goods such as:1, 2

- Stabilizer of emulsions and foams: critical for dough development during baking.

- Thickener: increases viscosity by thickening the aqueous phase.

- Fat-replacer: acts as a lubricant to help maintain creamy mouthfeel.

- Gluten-substitute: most effectively when combined with carboxymethylcellulose (CMC) in baked goods.

- Bulking agent

- Coating agent: film and barrier formation for coating.

- Binder

- Water retention: extends shelf-life.

- Controls water balance during freezing and thawing.

Nutrition

HPMC is considered a non-fermentable soluble dietary fiber, thus providing several health benefits including reduction of total and low density lipoprotein cholesterol, reducing risk factors of type 2 diabetes and aiding intestinal movements.3

Using HPMC in gluten-free baked goods helps with diet management for patients with celiac disease.3

Commercial production

HPMC is manufactured following this process:1, 2

- Alkalinization: wood pulp cellulose is treated with a 50 wt% sodium hydroxide solution in a reactor.

- Etherification: addition of methyl chloride followed by propylene oxide to introduce methoxy and propylene glycol groups, respectively.

- Neutralization: using hydrogen chloride solution.

- Purification: HPMC is washed several times with hot water, and filtered.

- Drying and sizing: the purified product is dried, ground to desirable particle size followed by packaging.

Application

HPMC can be used in the manufacture of several baked products, fillings, foams and coatings. It is a great alternative for gluten substitution in gluten-free baked products in combination with CMC.

Some considerations when adding HPMC to food products include:1, 3

- Solubilizing HPMC/CMC before addition for full performance.

- Consider the water activity of the systems, 5-10% of water may be needed in some formulations.

- HPMC should be added after proteins are activated.

- HPMC accommodates high sugar levels, up to...

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025