Agu . 06, 2024 14:23 Back to list

Exploring the Various Categories and Applications of HPMC in Modern Industries and Research

Understanding HPMC Types A Comprehensive Overview

Hydroxypropyl methylcellulose (HPMC) is a non-ionic, water-soluble polymer widely used in various industries, including pharmaceuticals, food, cosmetics, and construction. Its versatility and unique properties make it an essential ingredient in numerous applications. This article explores the different types of HPMC, their characteristics, and their applications.

What is HPMC?

HPMC is derived from cellulose, a natural polymer found in plant cell walls. The chemical structure of HPMC is modified to introduce hydroxypropyl and methyl groups into the cellulose backbone. This modification enhances its solubility in water and imparts specific functional properties, making HPMC an ideal choice for various formulations.

Types of HPMC

HPMC can be classified into different types based on the degree of substitution (DS), viscosity, and particle size. The three common types include

1. HPMC K Series - The K series is characterized by a high viscosity and is primarily used in pharmaceutical applications. The 'K' indicates the viscosity level, with higher numbers corresponding to greater viscosity. For instance, HPMC K4M has a low viscosity, while HPMC K100M has a high viscosity. These variations allow formulators to select the appropriate HPMC type for their specific needs. - Applications This series is predominantly used in controlled-release formulations, tablet coatings, and as a thickening agent in various products.

2. HPMC E Series - The E series features lower viscosity compared to the K series. The viscosity range typically ranges from 3,000 to 100,000 mPa·s. HPMC E is ideal for applications where minimal viscosity is required while still providing excellent film-forming properties. - Applications Commonly used in food products as a thickener and stabilizer, this series can also be found in cosmetics and personal care items.

3. HPMC F Series - The F series has the lowest viscosity and is designed for specialized applications such as in granulation and as a dispersant in suspensions. Its rapid solubility in cold water makes it advantageous in formulations where quick dissolution is necessary. - Applications Utilized in dry mix products, as well as in pharmaceutical and food industries, especially in instant food preparations.

hpmc types

Key Properties of HPMC

The unique properties of HPMC contribute to its widespread use

- Water Solubility HPMC dissolves in cold and hot water, providing versatility across various temperature applications. - Thickening Agent It acts as an effective thickening agent, enhancing the texture and viscosity of products. - Film-Forming HPMC creates flexible and cohesive films, making it a popular choice for coatings and protective applications. - Controlled Release In pharmaceutical formulations, HPMC enables controlled and prolonged release of active ingredients, optimizing therapeutic effects.

Applications of HPMC

Due to its multifunctional properties, HPMC finds applications in several fields

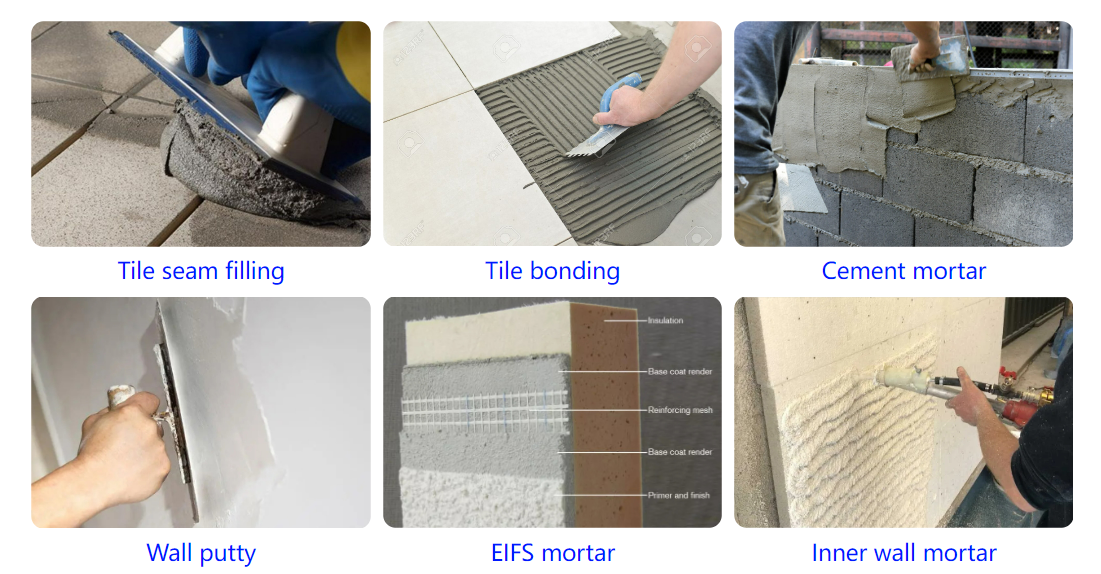

- Pharmaceuticals Used as a binder, coating agent, and controlled-release polymer in tablet formulations and capsules. - Food Industry Acts as a thickener, emulsifier, and stabilizer in sauces, dressings, and baked goods. - Cosmetics Used in creams, lotions, and gels, offering moisturizing and thickening benefits. - Construction HPMC enhances the workability of cementitious materials, improving adhesion and reducing water absorption.

Conclusion

HPMC's diverse types and unique properties make it a vital component in various industries. Understanding the differences among HPMC types, including the K, E, and F series, allows manufacturers and formulators to choose the right grade for their products. As industries continue to evolve and demand innovative solutions, HPMC will undoubtedly play a pivotal role in shaping the future of product formulations.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025