Հնվ . 11, 2025 10:00 Back to list

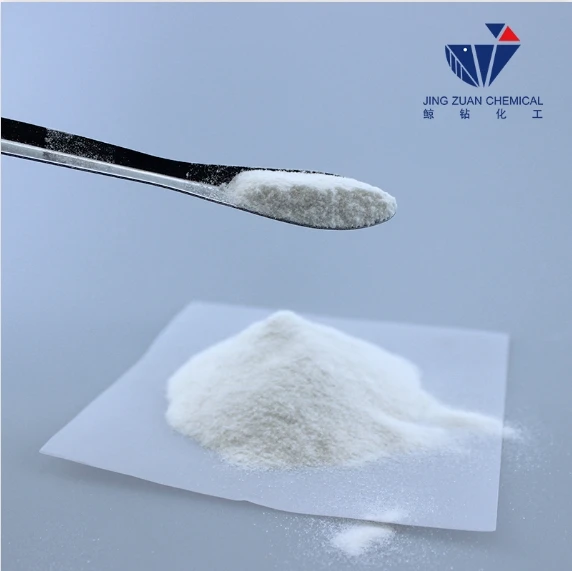

hpmc gel preparation

Cooling the gel is a crucial step where trust in precise temperature control systems comes into play. Slow cooling allows the gel to reach its optimal viscosity and clarity. Professional experience suggests that rapid cooling can cause inconsistencies in texture, whereas a controlled, gradual process results in a product with superior rheological properties. Incorporating additives or other active ingredients should occur after the gel has cooled to prevent degradation of heat-sensitive compounds. This is where the expertise in formulation becomes critical. Understanding the compatibility of HPMC with other substances is vital to ensure stability and effectiveness of the final product. Finally, the storage conditions, including temperature and humidity, can influence the shelf-life and performance of HPMC gel. Experts recommend storing the gel in airtight containers in a cool, dry place to maintain its quality over time. Proper labeling and batch testing, rooted in trustworthiness, further ensure that the final product meets the desired standards. In conclusion, the preparation of HPMC gel is a science that balances meticulous attention to detail with hands-on experience and deep understanding of materials. Mastery of this process not only ensures a high-quality product but also establishes credibility and authority in the field, benefiting both producers and consumers alike.

-

The Widespread Application of Redispersible Powder in Construction and Building Materials

NewsMay.16,2025

-

The Widespread Application of Hpmc in the Detergent Industry

NewsMay.16,2025

-

The Main Applications of Hydroxyethyl Cellulose in Paints and Coatings

NewsMay.16,2025

-

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

NewsMay.16,2025

-

HPMC: Application as a thickener and excipient

NewsMay.16,2025

-

Hec Cellulose Cellulose: Multi functional dispersants and high-efficiency thickeners

NewsMay.16,2025