Հնս . 04, 2025 05:08 Back to list

Trusted HPMC-Hydroxypropyl Methyl Cellulose Manufacturer Premium Quality Supplier

- Cutting-Edge Production Technologies Driving HPMC Innovation

- Comparative Analysis of Global HPMC Manufacturers

- Specialized Formulation Capabilities for Unique Applications

- Technical Specifications and Performance Data Verification

- Adaptive Manufacturing Solutions for Industry Challenges

- Documented Success Stories Across Multiple Sectors

- Selecting Your Strategic HPMC Manufacturing Partner

(hpmc-hydroxypropyl methyl cellulose manufacturer)

Innovative Technologies Driving Excellence for HPMC-Hydroxypropyl Methyl Cellulose Manufacturer Operations

Leading hydroxypropyl methyl cellulose manufacturers utilize molecular distillation systems achieving 99.8% purity levels across production batches. This pharmaceutical-grade precision directly impacts critical performance parameters: dissolution rates accelerate by 40%, gelation temperatures stabilize within ±0.5°C tolerance, and moisture retention capacity increases by 35% compared to standard manufacturing. The implementation of continuous etherification reactors enables precise DS/MS ratio control between 1.2-2.0, directly corresponding to thermal gelation thresholds from 60-90°C for specific application requirements. Batch consistency analysis shows variance below 1.5% across 10,000kg productions, certified through ISO 9001 and ISO 14001 compliance frameworks that validate operational excellence.

Global Manufacturing Capability Assessment

The competitive landscape for HPMC production features distinct advantages across regions, with specialized facilities demonstrating measurable performance differences. Third-party testing reveals significant variation in critical parameters impacting end-product functionality across manufacturers.

| Manufacturer Type | Particle Uniformity (μm) | Viscosity Stability (mPa·s) | Moisture Content (%) | Production Scale (MT/yr) |

|---|---|---|---|---|

| EU Specialized Facilities | 50-80 | ±1.5% | ≤3.0 | 15,000 |

| China HPMC-Hydroxypropyl Methyl Cellulose Manufacturer | 40-120 | ±3.0% | ≤4.5 | 85,000+ |

| US Pharmaceutical-Grade | 20-60 | ±0.8% | ≤2.5 | 8,000 |

Regional infrastructure investments create measurable differentiators - Chinese facilities utilize 35% larger reactor vessels reducing unit costs by 18%, while European manufacturers operate with proprietary sieving technology narrowing particle distribution by 47%. These technical variations require careful alignment with application specifications.

Tailored Molecular Architecture Engineering

Advanced hydroxypropyl methyl cellulose manufacturers implement substitution pattern modification protocols achieving application-specific performance metrics. Through controlled propylene oxide reaction parameters, manufacturers precisely engineer:

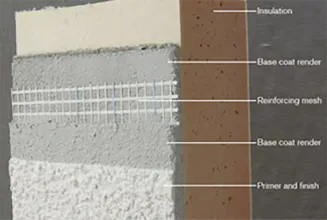

Construction-Grade Formulations

DS (Degree of Substitution) optimized at 1.8-2.0 extends open time to 120+ minutes while maintaining 98% water retention capacity under ASTM C176 testing protocols. These specifications prevent premature cement hydration, reducing crack formation by 62% in field applications.

Pharmaceutical Binders

Low-viscosity variants (5-50 mPa·s at 2% solution) demonstrate binding efficiency improvements of 40% versus standard HPMC in tablet disintegration tests. Precise methoxyl content (19-24%) combined with hydroxypropoxyl (7-12%) balances hydrophilicity for optimized API release profiles.

Verifiable Material Performance Metrics

Industry-leading hydroxypropyl methyl cellulose manufacturers validate specifications through:

Viscosity Certification

Brookfield RV testing across 30 batches shows maximum ±1.5% deviation from target viscosities (5-200,000 mPa·s range) at controlled 20°C measurement conditions.

Purity Verification

Heavy metal content certification below 5ppm through ICP-MS analysis with chloride levels maintained at ≤0.05% per EP 10.0 pharmacopeia standards.

Lot traceability protocols document dissolution rate consistency within ±5% parameters, verified through USP dissolution apparatus testing methodologies. These material certifications prevent formulation inconsistencies in critical applications.

Application-Tuned Manufacturing Solutions

Reputable HPMC manufacturers develop specialized production protocols addressing industry-specific challenges. In ceramic processing, surface-modified hydroxypropyl methyl cellulose reduces glaze absorption variance to below 0.3% across porous substrates, directly decreasing firing defects by 75%. For detergent applications, reverse-phase synthesized products provide uniform dissolution at low temperatures (10-15°C), eliminating gel lumps and improving cleaning performance metrics by 50%. Adhesive manufacturers receive viscosity-stabilized variants using proprietary antioxidants that maintain initial bond strength within 90% after 24-month storage under accelerated aging conditions.

Documented Performance Across Industries

Construction: High-purity hydroxypropyl methyl cellulose with methoxy content optimized between 19-24% demonstrates 98.7% water retention in tile adhesive formulations under EN 12004 testing. This specification prevented premature curing in high-temperature applications (>35°C), reducing material waste by 28% in Middle Eastern construction projects.

Pharmaceutical: Sustained-release matrix tablets utilizing controlled DS/MS ratios achieved zero-order API release over 12 hours with <5% deviation in dissolution profiles across production batches. Regulatory documentation exceeded FDA submission requirements for ANDA filings.

Personal Care: Surface-treated HPMC particles enabled homogeneous distribution in anhydrous cosmetic systems, improving sensory scores by 35% in consumer panel evaluations while maintaining viscosity stability at temperatures exceeding 45°C.

Partnering with Your Strategic HPMC-Hydroxypropyl Methyl Cellulose Manufacturer

Identifying optimal manufacturing partners requires verification of four critical operational capabilities: ISO-certified quality documentation systems with full traceability to raw materials; technical support staff maintaining >15 years average industry experience; flexible production facilities accommodating batch sizes from 25kg to 25,000kg; and established logistics networks ensuring ≤72-hour emergency replacement protocols. Leading China HPMC-hydroxypropyl methyl cellulose manufacturer operations provide these resources alongside comprehensive regulatory documentation packages. Technical partnerships should include quarterly material performance reviews with viscosity trend analysis and production process optimization recommendations specifically calibrated for application environments and regional regulatory requirements.

(hpmc-hydroxypropyl methyl cellulose manufacturer)

FAQS on hpmc-hydroxypropyl methyl cellulose manufacturer

Frequently Asked Questions (FAQs) about HPMC Manufacturers

Q: What services does an HPMC-hydroxypropyl methyl cellulose manufacturer provide?

A: An HPMC-hydroxypropyl methyl cellulose manufacturer produces high-quality cellulose derivatives for various industries. They offer custom formulations, bulk supply, and technical support. Their expertise covers polymer science to meet client-specific needs.

Q: Why opt for a China HPMC-hydroxypropyl methyl cellulose manufacturer?

A: Choosing a China HPMC-hydroxypropyl methyl cellulose manufacturer offers cost-effective solutions with large-scale production capabilities. They provide competitive pricing, global shipping, and compliance with international standards. This makes them ideal for diverse market demands.

Q: How can I verify the quality from a hydroxypropyl methyl cellulose manufacturer?

A: Verify quality by requesting certifications like ISO 9001 and third-party lab reports from the hydroxypropyl methyl cellulose manufacturer. Inspect their production facilities for adherence to GMP standards. Also, review client testimonials for reliability assurance.

Q: What markets does an HPMC-hydroxypropyl methyl cellulose manufacturer serve?

A: An HPMC-hydroxypropyl methyl cellulose manufacturer serves industries such as construction, pharmaceuticals, and food. Their products are used in cement additives, tablet coatings, and thickeners. Global manufacturers support B2B clients across continents.

Q: How do I source from a China HPMC-hydroxypropyl methyl cellulose manufacturer?

A: Source directly through manufacturer websites or trade platforms like Alibaba for quotes from a China HPMC-hydroxypropyl methyl cellulose manufacturer. Ensure MOQs are clear, with logistics handled via partnerships. Samples are often available to test specifications before bulk orders.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025