Դկտ . 05, 2024 15:30 Back to list

china hpmc factory

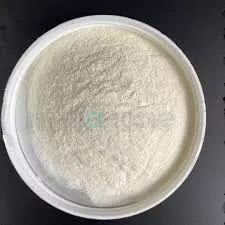

Introduction to HPMC Production in China

Hydroxypropyl Methylcellulose (HPMC) is a versatile and important chemical compound widely used in various industries, including pharmaceuticals, construction, food, and cosmetics. With the increasing demand for high-quality HPMC, China has emerged as a leading manufacturer and exporter of this valuable material. This article explores the production processes, applications, and the overall significance of HPMC factories in China.

Understanding HPMC

HPMC is a semi-synthetic polymer derived from cellulose, which is a natural polymer sourced from plant materials. Through a series of chemical processes, cellulose is modified to create HPMC, enhancing its solubility in water and making it more functional for various applications. The physical and chemical properties of HPMC, such as viscosity, gel formation, and stabilizing effects, make it an essential ingredient in many products.

The HPMC Manufacturing Process

HPMC production in China involves several critical steps

1. Raw Material Sourcing The primary raw material for HPMC production is cellulose, which can be sourced from various plant materials, including wood pulp and cotton. The quality of cellulose significantly influences the final product's quality.

2. Etherification The cellulose undergoes etherification, a chemical modification that introduces hydroxypropyl and methyl groups into its structure. This process is usually conducted in an alkaline environment, where cellulose reacts with propylene oxide and methyl chloride.

3. Purification and Drying After etherification, the mixture is purified to remove any unreacted chemicals and by-products. The purified HPMC is then dried to achieve the desired moisture content and particle size.

4. Quality Control Continuous quality assurance is vital for HPMC manufacturers. Chinese factories implement stringent quality control measures, ensuring that the final product meets international standards for purity, viscosity, and functionality.

Advantages of Chinese HPMC Factories

china hpmc factory

1. Cost-Effectiveness China’s vast supply chain and labor resources allow HPMC factories to produce goods at a lower cost compared to many Western countries. This affordability attracts international clients looking for high-quality yet competitively priced HPMC.

2. Advanced Technology Chinese manufacturers have invested significantly in the latest production technology, enhancing efficiency and product quality. This technological advancement ensures that Chinese HPMC is comparable to that produced in more established markets.

3. Capacity and Scale China has a considerable manufacturing capacity, with numerous factories dedicated to producing HPMC. This capacity allows for bulk production, meeting the demands of large-scale industries.

4. Export Market China is one of the largest exporters of HPMC globally. Manufacturers often have established distribution networks across the Americas, Europe, and Asia, facilitating a seamless export process.

Applications of HPMC

HPMC's versatility makes it suitable for a wide array of applications

- Pharmaceuticals In the pharmaceutical industry, HPMC is used as a binder in tablets, as well as in controlled-release formulations. Its ability to form gels and films also makes it ideal for coating tablets. - Construction HPMC is a critical ingredient in cement and mortar formulations, as it improves workability, reduces water usage, and enhances adhesion.

- Food Industry In the food sector, HPMC serves as a thickening agent and emulsifier, improving texture and stability in various products like sauces, dressings, and dairy products.

- Cosmetics Due to its film-forming properties, HPMC is used in cosmetics to provide a smooth application and long-lasting effects in products such as creams and lotions.

Conclusion

China's HPMC factories play a vital role in the global supply chain of this essential polymer. With their advanced manufacturing processes, cost-effective production, and diverse applications, these factories not only meet the high demands of various industries but also contribute significantly to China's economy. As the market for HPMC continues to expand globally, Chinese manufacturers are likely to remain at the forefront of innovation and quality in this field.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025