નવેમ્બર . 22, 2024 07:17 Back to list

hpmc types

Understanding HPMC Types A Comprehensive Overview

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used polymer in various industries, particularly in pharmaceuticals, food, and construction. HPMC is a semi-synthetic polymer derived from cellulose, and its unique properties make it an essential ingredient in many formulations. This article aims to provide a comprehensive overview of HPMC types, highlighting their characteristics and applications.

Understanding HPMC Types A Comprehensive Overview

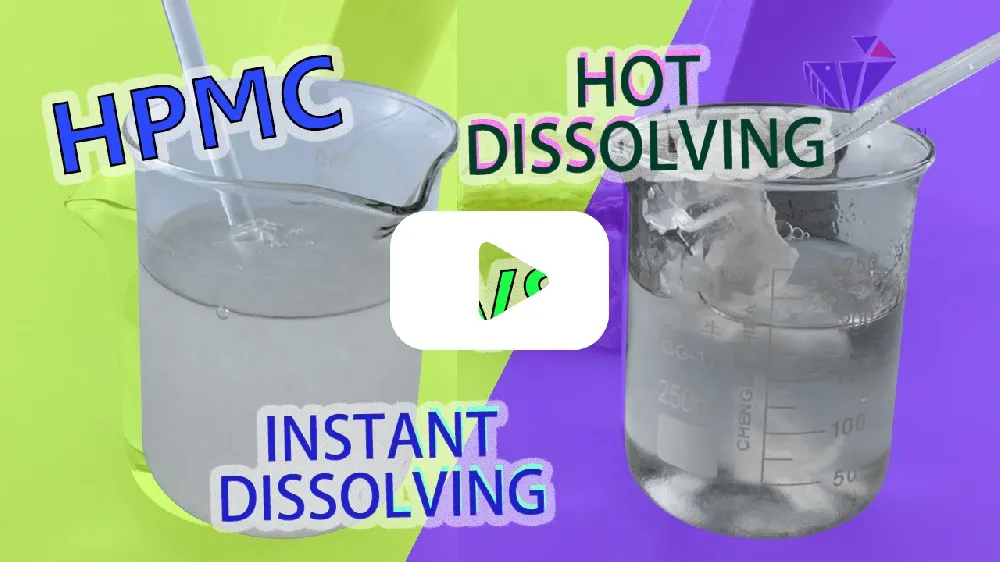

There are several types of HPMC, and they can be categorized based on the level of hydroxypropyl and methyl substitutions. Generally, the classification includes low, medium, and high viscosity grades. Low-viscosity HPMC is often used in applications requiring fast dissolution, such as tablet formulations. It has a lower degree of substitution, making it less viscous when dissolved in water. In contrast, high-viscosity HPMC offers greater thickening and gelling properties, which are beneficial in products such as adhesives, paints, and food items, where a more substantial texture is desired.

hpmc types

In the pharmaceutical industry, HPMC is widely used as a binder and film-forming agent in tablet formulations. Its ability to form a gel-like structure upon contact with water makes it an excellent choice for controlled-release drug delivery systems. The use of HPMC in pharmaceutical formulations ensures that the active ingredient is released gradually, enhancing its bioavailability and therapeutic effectiveness. Additionally, HPMC is often employed in ophthalmic solutions due to its lubricating properties, which provide comfort to patients.

In the food industry, HPMC is utilized as a thickener, stabilizer, and emulsifier. Its ability to retain moisture and improve texture makes it an ideal ingredient in baked goods, sauces, and dairy products. The use of HPMC as a fat replacer is also gaining popularity as consumers seek healthier alternatives. It allows manufacturers to reduce fat content while maintaining the desired mouthfeel and texture in their products.

Furthermore, HPMC is widely used in construction, particularly in cement and mortar formulations. It acts as a water-retaining agent, ensuring that the mixture remains workable for a more extended period. The inclusion of HPMC enhances the adhesion of materials, improving the overall durability and strength of constructions.

In summary, HPMC is a remarkable polymer with various types tailored for specific applications. Its unique properties, such as viscosity, solubility, and film-forming capabilities, make it indispensable across multiple industries. As research continues and technology advances, the applications of HPMC are expected to expand further, solidifying its role as a critical ingredient in numerous products. Understanding the different types of HPMC and their respective characteristics will enable industries to leverage this versatile polymer effectively.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025