feb . 14, 2025 19:31 Back to list

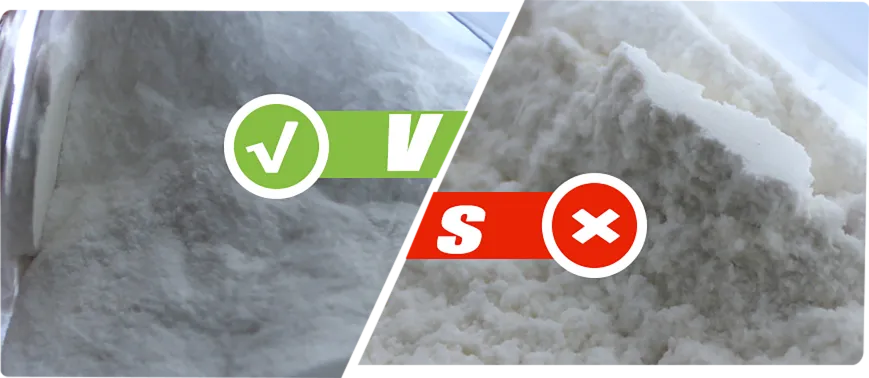

TILE BONDING ADDITIVES

The gelation temperature of Hydroxypropyl Methylcellulose (HPMC) is a pivotal characteristic that significantly impacts its application across various industries, particularly in pharmaceuticals, food, and construction. Understanding this property not only aids in the selection of the right grade of HPMC for specific applications but also enhances product performance and stability. This article delves into the intricacies of HPMC gelation temperature, drawing from real-world experiences, expert analysis, and authoritative insights.

In the food industry, HPMC is employed as a thickener and stabilizer in a variety of products including bakery goods, sauces, and dressings. An authoritative insight from culinary technologists highlights the importance of controlling the gelation temperature to maintain product consistency, prevent syneresis, and improve mouthfeel. Adjustments in the HPMC concentration and the application of specific grades can greatly influence textural properties, thereby enhancing consumer acceptance. The construction industry also leverages HPMC for its rheological properties in products like tile adhesives and mortars. Specialists in construction chemistry emphasize the need for precision in selecting HPMC grades with specific gelation temperatures to optimize setting times and improve workability under varying ambient temperatures. Trustworthiness in understanding and applying the gelation temperature of HPMC is built upon scientific rigor and practical validation. Developing expertise in manipulating this property involves not only theoretical knowledge but also empirical testing and iterative experimentation. Manufacturers often run extensive trials to fine-tune compositions that achieve the desired balance between gelation temperature and application-specific requirements. In conclusion, the gelation temperature of HPMC is a fundamental attribute that offers significant leeway in customizing its performance across diverse applications. Real-world experience, coupled with a thorough understanding of the underlying chemistry, enables industries to leverage this property effectively. Professionals seeking to maximize the utility of HPMC should prioritize comprehensive testing and evidence-based adjustments to tailor its characteristics to specific industrial needs. This strategic approach not only enhances product efficacy but also reinforces consumer trust through consistent quality and performance.

In the food industry, HPMC is employed as a thickener and stabilizer in a variety of products including bakery goods, sauces, and dressings. An authoritative insight from culinary technologists highlights the importance of controlling the gelation temperature to maintain product consistency, prevent syneresis, and improve mouthfeel. Adjustments in the HPMC concentration and the application of specific grades can greatly influence textural properties, thereby enhancing consumer acceptance. The construction industry also leverages HPMC for its rheological properties in products like tile adhesives and mortars. Specialists in construction chemistry emphasize the need for precision in selecting HPMC grades with specific gelation temperatures to optimize setting times and improve workability under varying ambient temperatures. Trustworthiness in understanding and applying the gelation temperature of HPMC is built upon scientific rigor and practical validation. Developing expertise in manipulating this property involves not only theoretical knowledge but also empirical testing and iterative experimentation. Manufacturers often run extensive trials to fine-tune compositions that achieve the desired balance between gelation temperature and application-specific requirements. In conclusion, the gelation temperature of HPMC is a fundamental attribute that offers significant leeway in customizing its performance across diverse applications. Real-world experience, coupled with a thorough understanding of the underlying chemistry, enables industries to leverage this property effectively. Professionals seeking to maximize the utility of HPMC should prioritize comprehensive testing and evidence-based adjustments to tailor its characteristics to specific industrial needs. This strategic approach not only enhances product efficacy but also reinforces consumer trust through consistent quality and performance.

Next:

Latest news

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025

Related PRODUCTS