tammi . 25, 2025 21:09 Back to list

grades of hpmc

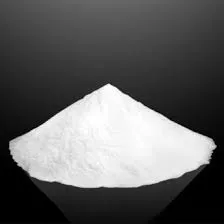

Hydroxypropyl Methylcellulose (HPMC) is a versatile material extensively used in various industries such as pharmaceuticals, construction, and food. Its various grades are tailored to optimize its functionality across different applications, making it a material of choice for many manufacturers and developers. Understanding the nuances between the different grades of HPMC can help businesses and manufacturers refine their product offerings and processes. Here's an in-depth exploration into the diverse grades of HPMC and their applications.

In terms of raw material sourcing, the origin and manufacturing process of HPMC significantly influence its quality and applicability across different grades. Manufacturers often seek suppliers who can offer certificates of analysis demonstrating compliance with industry standards. Moreover, understanding the supply chain, from raw material procurement to final product distribution, can affirm the reliability and trustworthiness of the HPMC grade used. As industries continue to seek sustainable and efficient solutions, the versatility of HPMC grades is meeting these demands. Advances in HPMC manufacturing have led to the production of bio-based alternatives, improving the product’s environmental footprint. Companies are increasingly adopting these eco-friendly grades to enhance sustainability efforts across diverse applications. For businesses exploring the procurement or application of HPMC, aligning with suppliers and stakeholders that prioritize innovation, compliance, and quality is key to leveraging its full potential. Industry experts advocate for ongoing collaboration with technical teams and engaging in continuous education on the latest HPMC advancements. Establishing a foundation of expertise through in-depth understanding of HPMC grades will ensure that products not only meet existing standards but also pave the way for future innovations. The strategic use of varying HPMC grades can markedly enhance product performance, operational efficiency, and market acceptance. Whether one is in pharmaceutical formulation, construction material innovation, or food manufacturing, the selection of the appropriate HPMC grade significantly impacts the outcome. As the demand for multifunctional ingredients grows, HPMC stands out with its adaptability, making it a valuable component across industries.

In terms of raw material sourcing, the origin and manufacturing process of HPMC significantly influence its quality and applicability across different grades. Manufacturers often seek suppliers who can offer certificates of analysis demonstrating compliance with industry standards. Moreover, understanding the supply chain, from raw material procurement to final product distribution, can affirm the reliability and trustworthiness of the HPMC grade used. As industries continue to seek sustainable and efficient solutions, the versatility of HPMC grades is meeting these demands. Advances in HPMC manufacturing have led to the production of bio-based alternatives, improving the product’s environmental footprint. Companies are increasingly adopting these eco-friendly grades to enhance sustainability efforts across diverse applications. For businesses exploring the procurement or application of HPMC, aligning with suppliers and stakeholders that prioritize innovation, compliance, and quality is key to leveraging its full potential. Industry experts advocate for ongoing collaboration with technical teams and engaging in continuous education on the latest HPMC advancements. Establishing a foundation of expertise through in-depth understanding of HPMC grades will ensure that products not only meet existing standards but also pave the way for future innovations. The strategic use of varying HPMC grades can markedly enhance product performance, operational efficiency, and market acceptance. Whether one is in pharmaceutical formulation, construction material innovation, or food manufacturing, the selection of the appropriate HPMC grade significantly impacts the outcome. As the demand for multifunctional ingredients grows, HPMC stands out with its adaptability, making it a valuable component across industries.

Next:

Latest news

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025

Related PRODUCTS