مه . 16, 2025 17:39 بازگشت به لیست

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

In construction engineering,mortar bonding agent, as an important bonding and filling material, is widely used in masonry, plastering, and tile laying. However, due to the differences in physical and chemical properties between the new and old mortar layers, as well as between the mortar and different substrates, there is a tendency for insufficient bonding strength, which can lead to quality hazards such as hollowing, cracking, and detachment, seriously affecting the safety and durability of building structures. Therefore, how to effectively improve the adhesion of mortar has become a crucial issue in the research and engineering practice of building materials. Latex bonding agents, as a functional material, play an increasingly important role in solving the above-mentioned problems.

Mortar bonding agent improves the workability of mortar

Some additives can improve the water retention of mortar, slow down water loss, ensure the full progress of cement hydration reaction, and enhance the strength and density of cement stone. At the same time, additives can also improve the workability of mortar, making it easier to construct and reducing defects generated during the construction process.

Mortar bonding agent enhances the physical connection between mortar and substrate

Some additives can improve the surface tension of mortar, enhance its wettability on the substrate surface, and enable mortar to better penetrate into the micropores on the substrate surface, forming a more effective mechanical bite.

Again, promote the chemical reaction between mortar and substrate. Some mortar adhesive additives can react chemically with cement hydration products or other active ingredients to generate substances with adhesive properties, thereby enhancing the chemical bonding force between mortar and substrate. For example, some polymer additives can form polymer cement composite structures, forming a strong bonding layer at the interface between mortar and substrate.

Mortar bonding agent improves the anti shrinkage performance of mortar

Mortar is prone to shrinkage during the hardening process, leading to stress concentration and reduced adhesion. Some additives can reduce the shrinkage rate of mortar, thereby reducing shrinkage stress and improving the bonding strength of mortar.

In summary, cement adhesive additive effectively enhances the adhesion between new and old mortar layers, as well as between mortar and different substrates, through multiple mechanisms working together. It can not only improve the overall integrity and durability of building structures, but also extend the service life of buildings and reduce maintenance costs. Therefore, in construction projects, the rational selection and use of cement bonding additives are crucial to ensuring project quality. With the continuous development of building material technology, new and efficient mortar adhesive additives will continue to emerge, providing more effective solutions to solve the problem of mortar adhesion and promoting the sustainable development of the construction industry.

mortar bonding agent FAQs

What are the main functions of a mortar bonding agent?

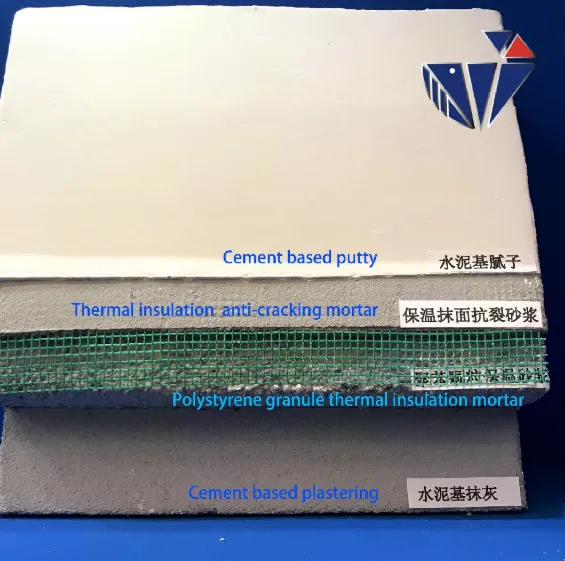

Mortar bonding agent is mainly used to improve the bonding performance of mortar, enhance the adhesion between new and old mortar layers, and between mortar and different substrates such as concrete, bricks, tiles, insulation boards, etc. At the same time, it can also improve the crack resistance, flexibility, and durability of mortar, ensuring long-term use without hollowing or falling off.

What are the common types of mortar bonding agents?

Polymers (such as redispersible latex powder and EVA lotion): improve flexibility and bonding strength.

Cellulose ethers (such as HPMC, HEMC): improve water retention and workability, reduce shrinkage cracking.

Organic silicon: enhances hydrophobicity and weather resistance.

Fibers (such as PP fibers and wood fibers): reduce cracking and improve impact resistance.

Special cement modifiers (such as rubber powder and silica fume): optimize hydration reaction and improve early strength.

How to choose a suitable mortar bonding agent?

The selection should be based on the type of substrate, construction environment, and performance requirements

High bonding requirements (such as tile adhesive, insulation system) → Polymer based (such as latex powder).

Porous substrate (such as aerated concrete) → water retaining agent (such as HPMC)+polymer.

Wet environment → Organic silicon hydrophobic agent.

Crack resistance requirements → Fiber based additives.

What is the recommended dosage for a mortar bonding agent?

Polymer latex powder: 1%~5% (based on the weight of the cementitious material).

Cellulose ether: 0.1%~0.5%.

PP fiber: 0.5~1.5kg/m3.

Organic silicon hydrophobic agent: 0.1%~0.5%.

The specific dosage needs to be determined through experiments to avoid excessive impact on strength or workability.

What are the precautions when using a mortar bonding agent?

Substrate treatment: Ensure that the substrate is clean and free of oil stains, and apply interface agent if necessary.

Mixing evenly: Additives should be thoroughly mixed with dry mortar to avoid clumping.

Construction environment: Avoid construction in high temperatures, strong winds, or rainy days to prevent rapid dehydration or freeze-thaw damage.

Maintenance: Proper moisturizing and maintenance (such as covering with film) should be carried out after construction to improve the final strength.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

اخبارAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

اخبارAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

اخبارAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

اخبارAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

اخبارAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

اخبارAug.07,2025