Abe . 01, 2024 13:30 Back to list

Optimizing HPMC Usage for Enhanced Gypsum Performance in Construction Applications

HPMC for Gypsum Enhancing Performance in Construction Materials

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used additive in the construction industry, particularly in gypsum-based materials. The incorporation of HPMC in gypsum products enhances their performance, workability, and longevity, leading to improved application and finishing characteristics. This article explores the benefits of using HPMC in gypsum formulations, its impact on construction applications, and the technical aspects that make it an essential component in modern construction materials.

HPMC for Gypsum Enhancing Performance in Construction Materials

One of the primary benefits of incorporating HPMC into gypsum formulations is improved water retention. Gypsum products, when mixed with water, can harden quickly, making it difficult for workers to achieve a smooth finish. HPMC acts as a water-retaining agent, preventing water evaporation during application and thereby extending the open time. This allows construction professionals ample time to work with the material, ensuring a higher quality finish. The extended workability not only improves application but also reduces the chances of cracks and defects in the final product.

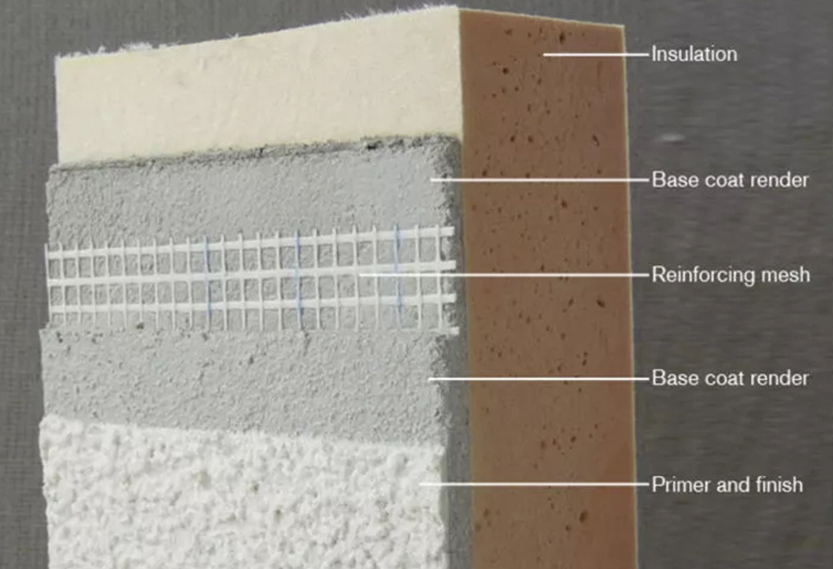

hpmc for gypsum

Moreover, HPMC contributes to enhanced adhesion properties. Gypsum-based materials can sometimes have difficulty adhering to various substrates, which can lead to delamination and other structural issues over time. With the addition of HPMC, the bonding strength between the gypsum and its substrate is significantly improved. This results in a more durable application, reducing maintenance needs and the likelihood of repair in the future.

In addition to its practical benefits, HPMC also plays a crucial role in the sustainability of gypsum products. As the construction industry moves towards more eco-friendly practices, the ability to reduce water usage and improve material efficiency becomes vital. HPMC allows for less water to be used during the mixing process while still achieving the desired performance characteristics. This not only helps in conserving water but also reduces the overall carbon footprint of construction projects.

When it comes to the application of HPMC in gypsum-based products, quality control is essential. The choice of HPMC grade—ranging from viscosity to hydroxypropyl content—must be tailored to the specific needs of the gypsum formulation. Each project may have different requirements based on environmental conditions, application techniques, and desired performance outcomes. Therefore, collaboration between HPMC suppliers and manufacturers of gypsum products is crucial to develop customized solutions.

In summary, the incorporation of Hydroxypropyl Methylcellulose in gypsum formulations significantly enhances their properties, making them more user-friendly and durable. With improved water retention, adhesion, and overall performance, the use of HPMC contributes to a more efficient and sustainable building process. It is a perfect illustration of how advanced chemical additives can elevate traditional materials, leading the construction industry into a more innovative and environmentally conscious future. As the demand for high-performance building materials continues to grow, HPMC stands out as an indispensable component in the evolution of gypsum-based products.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025