dets. . 23, 2024 06:15 Back to list

Exploring the Role of HPMC in Pharmaceutical Excipients and Formulation Development

The Role of HPMC Excipients in Pharmaceutical Formulations

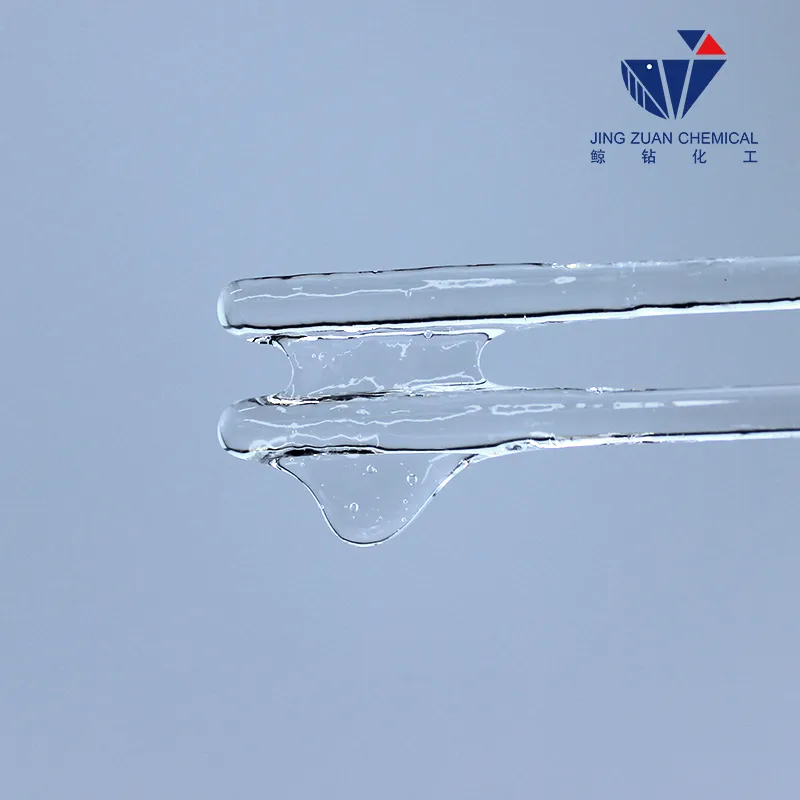

Hydroxypropyl Methylcellulose (HPMC) is a versatile excipient widely used in the pharmaceutical industry. Known for its excellent film-forming, gel-forming, and thickening properties, HPMC has found a prominent place in both solid and liquid dosage forms. In this article, we will explore the significance of HPMC as an excipient, its key properties, applications, and advantages in drug formulations.

Understanding HPMC

HPMC is a non-ionic cellulose ether derived from natural cellulose. Through a chemical modification process, hydroxyl and methoxy groups are introduced to the cellulose backbone, enhancing its solubility in water. HPMC is typically available in various grades, differing in viscosity and polymer chain length, which allows formulators to select the appropriate type based on the specific requirements of their formulations.

Key Properties of HPMC

1. Controlled Release One of the most significant properties of HPMC is its ability to form controlled-release formulations. The polymer’s gel-forming ability can be utilized to create matrices that release active pharmaceutical ingredients (APIs) gradually over time, thereby improving therapeutic efficacy and reducing the frequency of dosing.

2. Film-Forming HPMC excels in its film-forming capabilities, making it an ideal choice for coating tablets and granules. This property not only enhances the appearance of the pharmaceutical products but also protects sensitive APIs from moisture and light, ensuring their stability.

3. Stability and Compatibility HPMC is known for its excellent compatibility with a wide range of APIs, making it a suitable candidate for various formulations. Furthermore, HPMC is stable under a wide range of pH conditions, which is crucial for ensuring the efficacy of drugs in different environments within the gastrointestinal tract.

4. Thickening and Gelling Agent In liquid formulations, HPMC serves as a thickening agent, improving the viscosity and texture of solutions, suspensions, and emulsions. This property is particularly valuable in developing formulations such as syrups, where a specific consistency is required for patient acceptability.

Applications of HPMC in Pharmaceuticals

The applications of HPMC as an excipient are extensive, spanning across different dosage forms

- Tablets HPMC is used in both immediate-release and controlled-release tablet formulations. When used in matrix systems, it helps modulate the release of drugs by forming a gel barrier that regulates the drug dissolution rate.

hpmc excipient

- Capsules HPMC is also employed in the production of HPMC capsules, a plant-based alternative to gelatin capsules. These vegetarian capsules cater to a growing market segment for individuals seeking non-animal-derived products.

- Oral Solutions and Suspensions HPMC's thickening properties make it suitable for formulating oral solutions and suspensions, providing better mouthfeel and stability to these liquid dosage forms.

- Topical Formulations In creams and gels, HPMC acts as a gelling agent and stabilizer, imparting desirable texture and spreadability properties. Its moisture-retaining capabilities make it suitable for hydrophilic topical applications.

Advantages of Using HPMC in Formulations

The incorporation of HPMC in pharmaceutical formulations offers numerous benefits

- Improved Patient Compliance The ability to design controlled-release formulations means patients can adhere more easily to dosing regimens, ultimately enhancing treatment outcomes.

- Enhanced Drug Stability By providing a protective barrier for drugs, HPMC minimizes degradation from environmental factors, thus improving the shelf life of pharmaceutical products.

- Versatility HPMC’s range of properties allows formulators to customize formulations extensively, accommodating various drugs and therapeutic indications.

- Compatibility with Active Ingredients The high compatibility of HPMC with many APIs ensures that the desired therapeutic effect is achieved without adverse interactions, thus maintaining the integrity of the drug's pharmacological profile.

Conclusion

HPMC is undeniably a valuable excipient in the realm of pharmaceuticals, contributing significantly to the development of effective, stable, and patient-friendly formulations. As the demand for innovative drug delivery systems continues to grow, HPMC will likely play an increasingly crucial role in advancing pharmaceutical technology. Its multitude of properties and applications positions it as an essential component in the formulation toolbox for pharmaceutical scientists and formulators around the world. As research in this area progresses, HPMC may pave the way for the development of new formulations that enhance patient care and treatment outcomes.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025