Δεκ . 24, 2024 19:32 Back to list

Exploring Different Types of HPMC and Their Applications in Various Industries

Understanding HPMC Types An In-Depth Overview

Hydroxypropyl methylcellulose (HPMC) is a versatile and widely used cellulose ether derived from natural cellulose. It has gained popularity across various industries due to its unique properties, including gel formation, thickening, emulsifying, and film-forming capabilities. In this article, we will explore the different types of HPMC, their applications, and the factors influencing their selection.

Types of HPMC

HPMC is categorized based on the degree of substitution of hydroxypropyl and methoxy groups, which influences its solubility and viscosity. The primary types include

1. HPMC K (Methoxy and Hydroxypropyl Content) - This category is characterized by a specific viscosity range and a defined content of methoxy and hydroxypropyl groups. HPMC K types are classified by their viscosity, such as K4M, K100M, and K15M, where ‘K’ indicates the viscosity level in centipoises (cP). - Applications HPMC K types are widely used in pharmaceuticals as a binding agent in tablets and are also found in the production of controlled-release formulations.

2. HPMC E (Enhanced Solubility) - HPMC E types exhibit enhanced solubility in cold water compared to standard HPMC K types. This group contains unique structural features that promote rapid dissolution. - Applications Mainly utilized in food applications and cosmetic products, HPMC E is effective as a thickener and stabilizer.

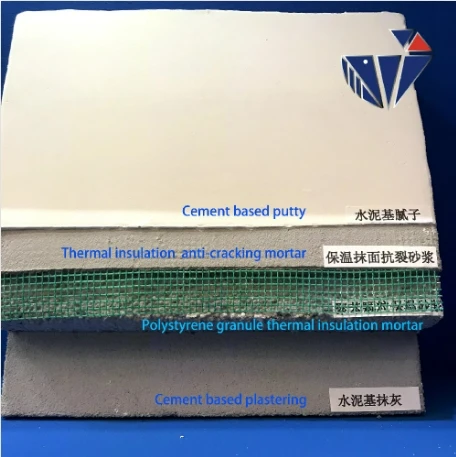

3. HPMC M (Medium Viscosity) - HPMC M types are designed to provide medium viscosity and are not as soluble as E types but demonstrate improved viscosity control over K types. - Applications Commonly used in construction materials, HPMC M serves as a water-retaining agent in cement-based grouts and tile adhesives.

4. HPMC S (Specialized Grades) - This classification involves grades of HPMC tailored for specific applications, including pharmaceutical and food industries. - Applications Depending on the intended use, specialized grades of HPMC can be either fast-dissolving or slow-releasing agents in drug formulations.

Key Properties of HPMC

The unique properties of HPMC make it an essential ingredient in numerous applications

hpmc types

- Water Solubility Depending on its chemical structure, HPMC can exhibit different solubility profiles, making it suitable for various formulations. Water-soluble HPMCs help achieve desired viscosity and texture in products. - Thermal Stability HPMC demonstrates excellent thermal stability during processing, which is crucial for heat-sensitive applications such as food and pharmaceuticals. - Film-Forming Ability Due to its film-forming properties, HPMC is instrumental in coatings for tablets in pharmaceuticals as well as in edible films for food products.

- Viscosity Control HPMC can be tailored to achieve specific viscosity levels, which is important for ensuring product consistency and performance in formulations.

Selection Criteria

When choosing the right type of HPMC for a specific application, several factors should be considered

1. Viscosity Requirements Identify the desired viscosity level for your formulation and choose the appropriate HPMC grade accordingly.

2. Solubility Depending on whether cold or hot water solubility is needed, select the appropriate type of HPMC that meets these criteria.

3. Application Compatibility Some types of HPMC are better suited for specific applications (e.g., pharmaceutical vs. construction), so understanding the end-use is vital.

4. Regulatory Compliance In applications like food and pharmaceuticals, ensure that the chosen HPMC grade complies with relevant regulations and standards.

Conclusion

HPMC is an essential component in many industries due to its unique properties and versatility. Understanding the different types of HPMC, along with their applications and selection criteria, can help formulators optimize their products for performance and compliance. As industries continue to evolve and demand more specialized solutions, HPMC remains a foundational ingredient for innovation and quality.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025