Νοέ . 06, 2024 02:36 Back to list

Exploring Advanced HPMC Applications and Innovations for Modern Pharmaceuticals

Understanding HPMC A Key Ingredient in Pharmaceuticals and Beyond

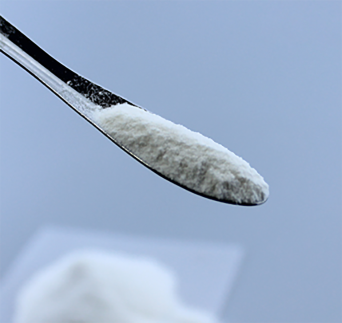

Hydroxypropyl Methylcellulose (HPMC) has emerged as an essential compound in various industries, notably in pharmaceuticals, food, and construction. As a cellulose derivative, HPMC is known for its unique properties that enhance the performance of formulations. This article will delve into the characteristics, applications, and significance of HPMC, particularly focusing on its role in the pharmaceutical sector.

What is HPMC?

HPMC is a semi-synthetic polymer derived from cellulose, a natural polymer found in plant cell walls. The modification process involves the substitution of hydroxyl groups with hydroxypropyl and methyl groups, resulting in a compound that exhibits improved solubility and versatility. The chemical structure allows HPMC to form films, thicken solutions, and act as a stabilizer in emulsions.

Properties of HPMC

1. Solubility HPMC is soluble in water, which makes it an ideal choice for various applications where a stable and homogenous solution is critical. Its solubility can be controlled by adjusting the degree of substitution, allowing formulators to customize the properties of their products.

2. Viscosity HPMC is available in various viscosity grades, which can be tailored to meet specific requirements. This property is particularly important in pharmaceutical formulations, where viscosity can influence the release characteristics of drugs.

.

4. Non-toxic and Biocompatible Being derived from natural cellulose, HPMC is considered safe for use in food and pharmaceuticals. It is non-toxic and biocompatible, making it suitable for applications in medical devices and drug delivery systems.

hpmc 200000

Applications in Pharmaceuticals

1. Binder in Tablet Formulations HPMC serves as an effective binder in tablet manufacturing. It helps in the uniform distribution of active pharmaceutical ingredients (APIs) and ensures the tablets maintain their integrity during storage and handling.

2. Controlled Drug Release One of the most notable applications of HPMC is in controlled-release formulations. Its ability to form gels in the presence of water allows for a sustained release of the drug over time, improving therapeutic efficacy and patient compliance.

3. Suspending and Thickening Agent HPMC acts as a suspending agent in liquid formulations, ensuring that solid particles remain evenly dispersed. Additionally, its thickening properties enhance the texture and stability of syrups and suspensions.

4. Film Coating In tablet and capsule manufacturing, HPMC serves as an effective film coating agent. The coatings can mask unpleasant tastes, improve the appearance of the product, and control the release of the medication.

5. Hydrogels for Drug Delivery The ability of HPMC to form hydrogels makes it an excellent candidate for localized drug delivery systems. These hydrogels can encapsulate drugs and release them in a controlled manner, improving therapeutic outcomes, especially in ocular and transdermal applications.

Conclusion

HPMC stands out as a versatile and essential polymer in the pharmaceutical industry. Its unique properties make it invaluable in creating effective drug formulations that enhance patient compliance and therapeutic outcomes. As research and development continue to innovate in the field of pharmaceuticals, HPMC will likely play a crucial role in the formulation of next-generation drug delivery systems and therapeutic solutions. By understanding and harnessing the capabilities of HPMC, scientists and formulators can create safer, more effective medications that meet the needs of patients around the world.

-

tile-bonding-additives-for-stronger-bonds

NewsAug.22,2025

-

construction-grade-rdp-for-wholesale-needs

NewsAug.22,2025

-

trusted-wholesale-hec-partners

NewsAug.22,2025

-

hec-solutions-for-industrial-excellence

NewsAug.22,2025

-

construction-additives-need-hpmc-essentials

NewsAug.22,2025

-

hpmc-versatile-cellulose-ether-for-industries

NewsAug.22,2025