Jan . 01, 2025 03:03 Back to list

HPMC Production Process and Its Industrial Applications for Efficient Manufacturing

The HPMC Factory Innovations in the Production of Hydroxypropyl Methylcellulose

In today's rapidly evolving industrial landscape, the demand for high-quality, versatile materials is on the rise. One such material that has garnered significant attention in various industries is Hydroxypropyl Methylcellulose (HPMC). An essential component in pharmaceuticals, construction, cosmetics, and food production, HPMC is a cellulose ether that offers unique properties, including thickening, binding, and emulsifying capabilities. This article delves into the innovative processes and implications of HPMC production in a dedicated factory setting.

Understanding HPMC

Hydroxypropyl Methylcellulose is a non-ionic, water-soluble polymer derived from cellulose, the most abundant organic polymer on Earth. By modifying cellulose through etherification, HPMC is created to enhance its functional properties. Its applications are vast in pharmaceuticals, it serves as a binder for tablets; in construction, it acts as a thickening agent in mortars and cements; and in food, it's used as a stabilizer in various formulations. The growing reliance on HPMC across sectors underscores the need for robust production facilities.

The Manufacturing Process

A modern HPMC factory embodies cutting-edge technology and adherence to strict quality standards. The manufacturing process typically involves several key stages

1. Raw Material Procurement High-quality cellulose is sourced, often from wood pulp or cotton linters. The quality of raw materials directly impacts the properties of the final HPMC product, making this step critical.

2. Etherification The core of HPMC production lies in the etherification process, where cellulose is chemically modified by reacting it with propylene oxide and methyl chloride. This step requires precise control over temperature and reaction time to ensure the desired degree of substitution and consequent properties of the HPMC.

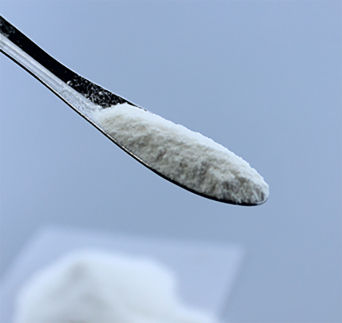

hpmc factory

3. Drying and Milling Post-etherification, the mixture must be carefully dried and milled. This process transforms the material into a fine powder, which can easily dissolve in water, catering to its intended applications.

4. Quality Control Rigorous testing is performed to ensure the HPMC meets industry standards. This includes assessing viscosity, solubility, and particle size distribution, which are crucial for its performance in end applications.

5. Packaging and Distribution Finally, the finished product is packaged using environmentally-friendly materials and distributed to various industries. Effective logistics play an essential role in ensuring timely delivery and maintaining product integrity.

Innovations and Sustainability

HPMC factories are at the forefront of innovation, continuously improving production methods to enhance efficiency and reduce environmental impact. Automation and real-time monitoring systems are becoming commonplace, allowing for better control over the production process and minimizing human error. Additionally, energy-efficient machinery and waste recycling practices are being adopted to foster sustainability in manufacturing.

Moreover, manufacturers are exploring the use of renewable raw materials and biodegradable additives to align with global sustainability goals. As consumers become increasingly environmentally conscious, the demand for eco-friendly products is mirrored in the evolution of HPMC production methods.

Conclusion

The HPMC factory stands as a testament to the fusion of tradition and innovation in modern manufacturing practices. As industries continue to evolve, the need for reliable and versatile materials like Hydroxypropyl Methylcellulose will only increase. In response, HPMC factories are not only enhancing their production techniques but also committing to sustainable practices that ensure the well-being of both consumers and the planet. As we look to the future, the continued development of HPMC will likely usher in new applications and innovations that further extend its influence across various fields.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025