nov . 25, 2024 08:46 Back to list

HPMC Gelation Temperature and Its Impact on Drug Delivery Systems

Understanding HPMC Gelation Temperature Significance and Applications

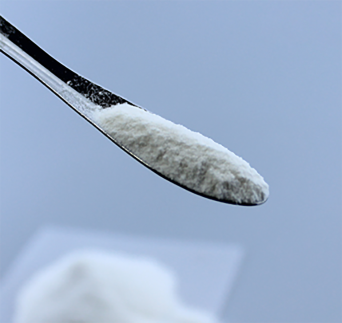

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose derivative widely used in various industries, including pharmaceuticals, food, and construction. One of the critical properties of HPMC is its gelation temperature, which plays a crucial role in determining its functionality in different applications. Understanding HPMC gelation temperature is essential for optimizing its use and ensuring the desired performance of products.

What is HPMC?

HPMC is a non-ionic, water-soluble polymer derived from cellulose. Its chemical structure includes hydroxypropyl and methyl groups, which impart specific properties, such as solubility, viscosity, and gel formation. The ability of HPMC to form gels upon heating is significant for many applications, contributing to texture, stability, and overall product performance.

The Importance of Gelation Temperature

Gelation temperature refers to the temperature at which HPMC undergoes a phase transition, resulting in the formation of a gel structure. This property is influenced by several factors, including polymer concentration, molecular weight, and the presence of salts or other additives. The gelation temperature is critical in applications such as

1. Pharmaceuticals In drug formulation, HPMC is used as a binder, thickener, and release agent. Understanding its gelation temperature helps formulate controlled-release medications, ensuring the ideal release profile. For instance, in hot melt extrusion processes, maintaining the appropriate temperature is crucial to achieving the desired drug release characteristics.

2. Food Industry HPMC is often utilized as a food thickener, emulsifier, and stabilizer. The gelation temperature affects the mouthfeel and texture of food products, such as sauces, dressings, and dairy items. By controlling the gelation temperature, manufacturers can enhance the sensory attributes of food, providing an improved consumer experience.

3. Cosmetics and Personal Care In personal care products, HPMC serves as a thickener and film-forming agent. The gelation temperature influences the stability, viscosity, and application of creams and gels, ensuring that they maintain their desired consistency during formulation and use.

hpmc gelation temperature

4. Construction HPMC is commonly used as a bonding agent in mortars and adhesives. Its gelation temperature is vital for optimizing workability and adhesion properties. By understanding this temperature, construction professionals can tailor formulations to achieve specific performance characteristics, such as open time and setting speed.

Factors Affecting Gelation Temperature

Several factors influence the gelation temperature of HPMC, including

- Molecular Weight Higher molecular weight HPMC typically exhibits higher gelation temperatures. This is because increased chain length leads to greater intermolecular interactions, necessitating higher temperatures to disrupt these forces and induce gelation.

- Concentration The concentration of HPMC in solution significantly impacts gelation temperature. As concentration increases, the gelation temperature tends to rise due to increased polymer interactions and network formation.

- Additives The presence of salts, surfactants, or other additives can lower the gelation temperature by affecting the interactions between polymer chains. Understanding these interactions allows formulators to adjust the gelation behavior for specific applications.

Conclusion

In summary, the gelation temperature of HPMC is a vital property that influences its performance across various industries. By understanding the factors that affect gelation temperature, formulators can optimize HPMC formulations to achieve specific functional characteristics. Whether in pharmaceuticals, food, cosmetics, or construction, knowing how to manipulate gelation temperature enables manufacturers to create high-quality products that meet consumer expectations and industry standards. As research continues to evolve, the understanding of HPMC gelation and its applications will undoubtedly expand, opening new avenues for innovation in material science and product development.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025